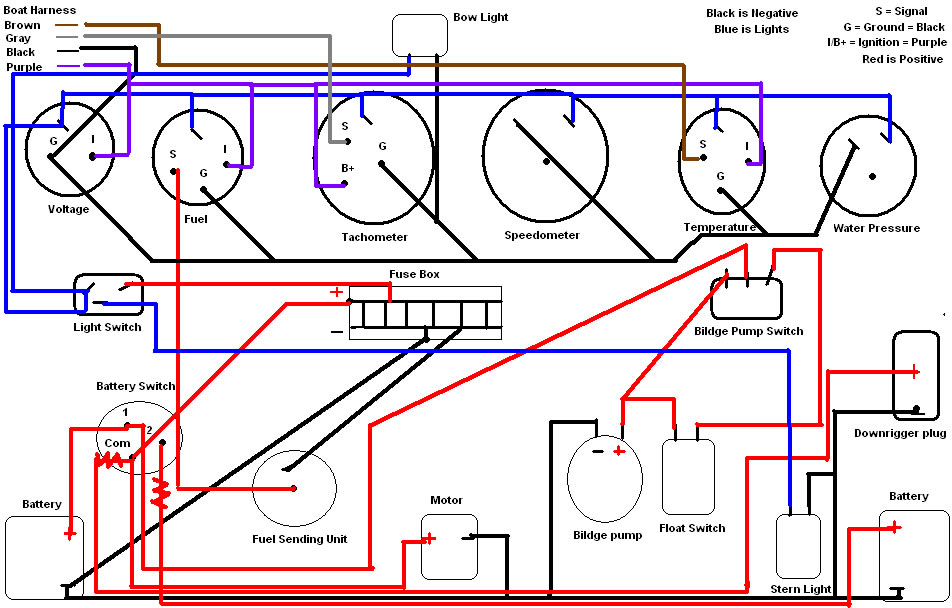

The vast majority of recreational boats in service today are still using analogue instrumentation systems. This way even if your battery switch is off if your boat starts filling with water the pump will still kick on.

Lo 6214 Boat Fuel Sender Wiring Diagram

How to wire boat gauges. For example a trolling motor on a 20 foot boat should have 4 or 6 gauge wire for best battery utilization. Id rather have a dead battery than a swamped boat. Some use a screw to make the connection to the terminal on the fuel gauge or a clip for the connection while others require you to solder the wires to the terminals. The rpm gauge called a tachometer tells you the number of revolutions per minute rpm that your boat motors crankshaft is turning. Study schematics never be afraid to attempt the job and if necessary enlist expert help in the form of a reputable dealer or manufacturer and you can cut the down time significantly. Engine instrument gauges fall into three categories and there are differences in the terminals and wiring.

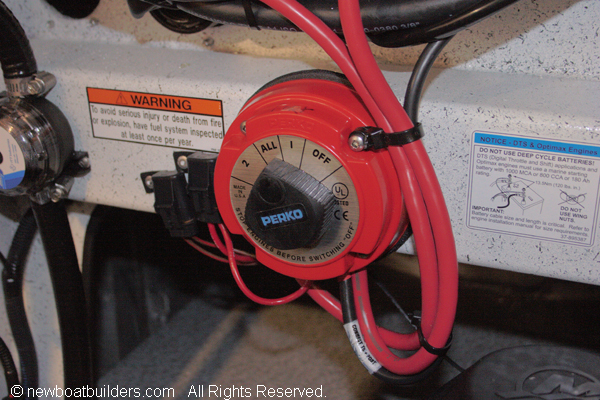

More modern digital nmea networked and multifunction gauges may be all the buzz but the reality is that most boats are still equipped with the same analogue set ups that have been in use for decades. Its pretty standard in boat wiring to bypass the main battery switch for one thing. Boat owners should never cut corners on wiring jobs. If your boat needs a new fuel gauge odds are youll want to install it because its too simple to take to a repair shop or your boat dealer. If you know what wire to connect to which terminal the only decision you. For example running out of fuel because of a broken fuel gauge can cause your boat to run aground when a tide drives you ashore.

Wiring a fuel gauge is much the same as wiring any other gauge on your boat. Engine instrument wiring made easy. Items you will need. Working marine fuel gauges help you avoid embarrassing situations such as running out of fuel as you approach a boat club raft up. By will charpentier. Related how to test outboard starters.

Euthanizing of a. Dangar marine 147909 views. Boats and maintenance 10 basic rules for wiring a boat. Whether youre installing a new rpm gauge or simply upgrading the one that. The rpm gauge lets you know when you approach the highest number of revolutions per minute that your motor can attain without hemorrhaging internally so that you dont exceed that rate. How to wire a marine fuel tank gauge.

How to troubleshoot fix a boat fuel gauge fuel sender. Wiring the electrics on a boat pt 1 duration. The wires may follow a seemingly unusual path but the system works. One wire comes from the ignition to the instrument one wire comes from the sensor to the instrument one wire comes to the instrument light and one wire from the instrument goes to the boats common ground. Every problem cannot be solved with this checklist but it will give you a good starting place. Disconnect your boats.

Malfunctioning fuel gauges can also lead to safety hazards and emergencies. The boats bilge pump float switch. Different brands of gauges and different gauges from the same manufacturer have a variety of connection types. Most importantly sae wire is up to 12 percent smaller than american wire gauge awg boat cable which means that in many applications larger gauge wire must be used to stay within the voltage drop limits recommended by experts see our west advisor on marine wire size and ampacity. The wire charts found in chapmans piloting and other publications are all for awg wire like that made by our supplier ancor not sae type wire. In general wiring on boats should be of the stranded type.