So can i use a small 15mm 2c swa. This is perfectly normal and the correct way to do it once these connections are made you are ready to turn the power back on and the submersible pump should operate according to the position of the float switch.

Installing A Bilge Pump Light Trailering Boatus Magazine

How to wire a float switch to a pump. Mount or suspend your switch at the desired level get your wires into a water tight junction box or out of the liquid containment area and then into a junction box check the connections back to your control and power equipment and youre done. I have been asked to fot a float switch to a pump not a problem but the distance is 525m. Ensure they are restrained so they dont fall and get damaged as they intake air 2. Ensure the bilge pump is safely mounted on the bilge. With the cable being so long it affects the price alot should it require a larger cable. Reconnect the negative cable to the batterys negative terminal.

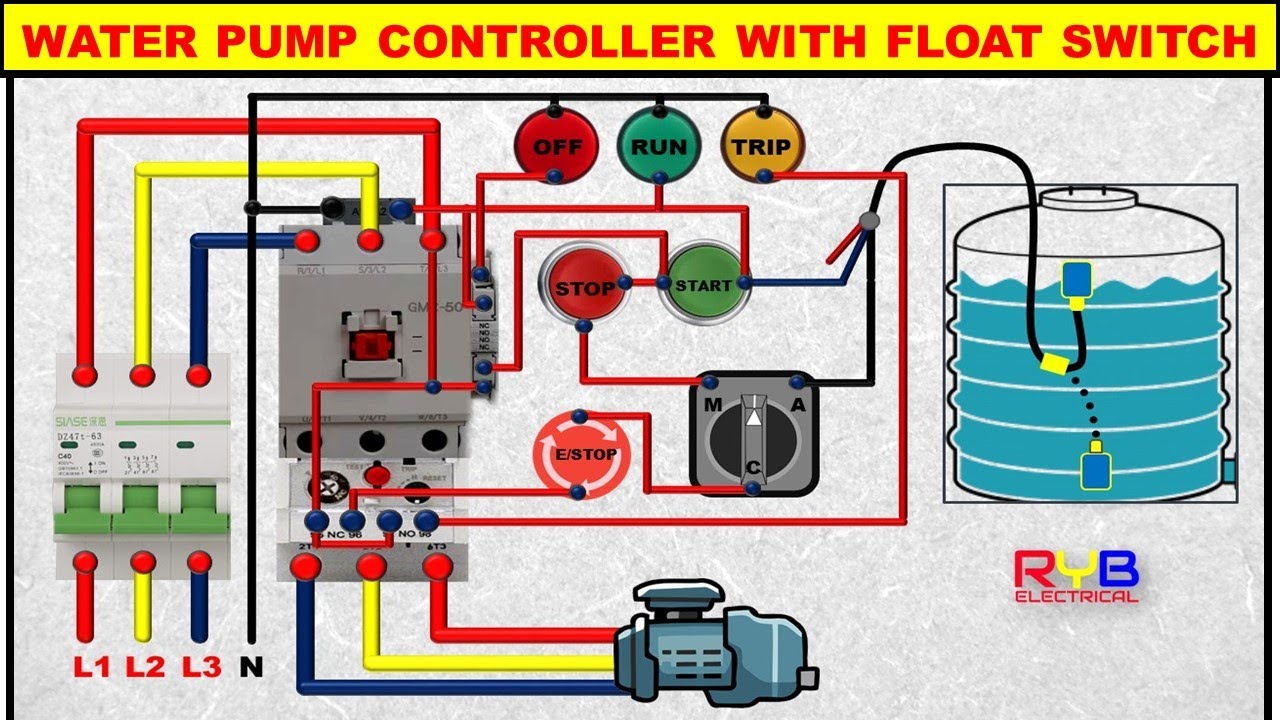

Now there is no load on the float switch as i will be using a contactor to switch the pump locally. Most float switches have a white and black wire which means you will most likely have a white to black connection. Any help will be appreciated. A two wire float switch that can easily be used for turning a pump on or off. Yesterday at 504 pm 2 i assume it controls the contactor so there must be load on it and. Then cover them with a wire nut.

If the float switch protects an air conditioning system disconnect the furnaces transformer wire that connects to the red thermostat wire and then connect the float switch lead to the transformers wire. I have now got a new pump cut the wire to the pump to install the excising float switch i have but on cutting the pump wire noticed it has four core wire rather than the three core previous. Mount on your float switch 4. There is a mounting bracket available for the kari float switch that uses a snug wedge to fix the cable into place. Steps for wiring bilge pump with float switch 1. Twist the end of one float switch lead around the end of the wire that connects to the power source.

Connect the wire that runs directly to the bilge pump to one of the switched terminals on the three way switch. I see no reason not as there is no load to take into account. Here are the ways you can use to wire float switch bilge pump safely. Use brackets to fasten bilge pump or with epoxy so you can attach bolts at the bottom of the bilge that will be the mounting studs. Connect one of the wires from the float switch to each of the switched terminals on the three way switch. This bracket can be attached to a wall or a rail using a simple bolt or screw.

One leg of the float switch will connect to the hot wire from the panel. Use the smooth interior hose to connect your pump with discharge. Float switch installation requires you to mount the device with some way of fixing the cable above the tank or well. The other leg will connect to the hot wire from the pump. I have a sparky friend who will help but hes snowed under and cant get here till a few weeks. I have had a look on the web and cant see any instructions on how to do it using a four core does anyone have any advice or diagrampicture or link they can send me on this.