Float switch wire volt drop hi guys and gals. Well pump from pumptec.

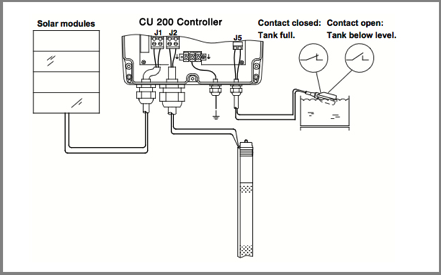

Nemo Systems Guide Nemo Solar Dc Submersible Well Pumps

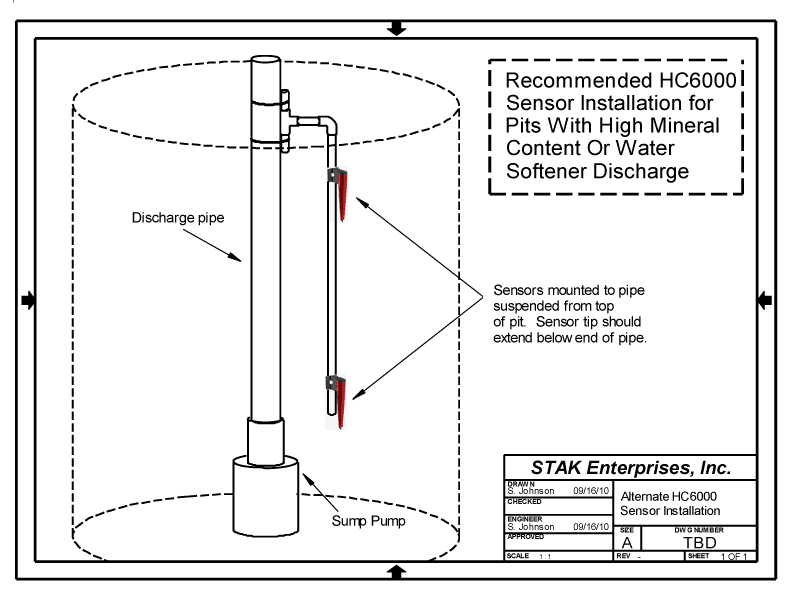

How to wire a float switch to a well pump. I have a sparky friend who will help. Slap your adjustable wrench around the flats on the gauge and unscrew it. Ensure you get some mounting bracket in the float switch which requires a comfortable wedge for fixing the wire in place. The bracket is easily attached to the roll or even wall with a screw or bolt. So can i use a small 15mm 2c swa. Most float switches have a white and black wire which means you will most likely have a white to black connection.

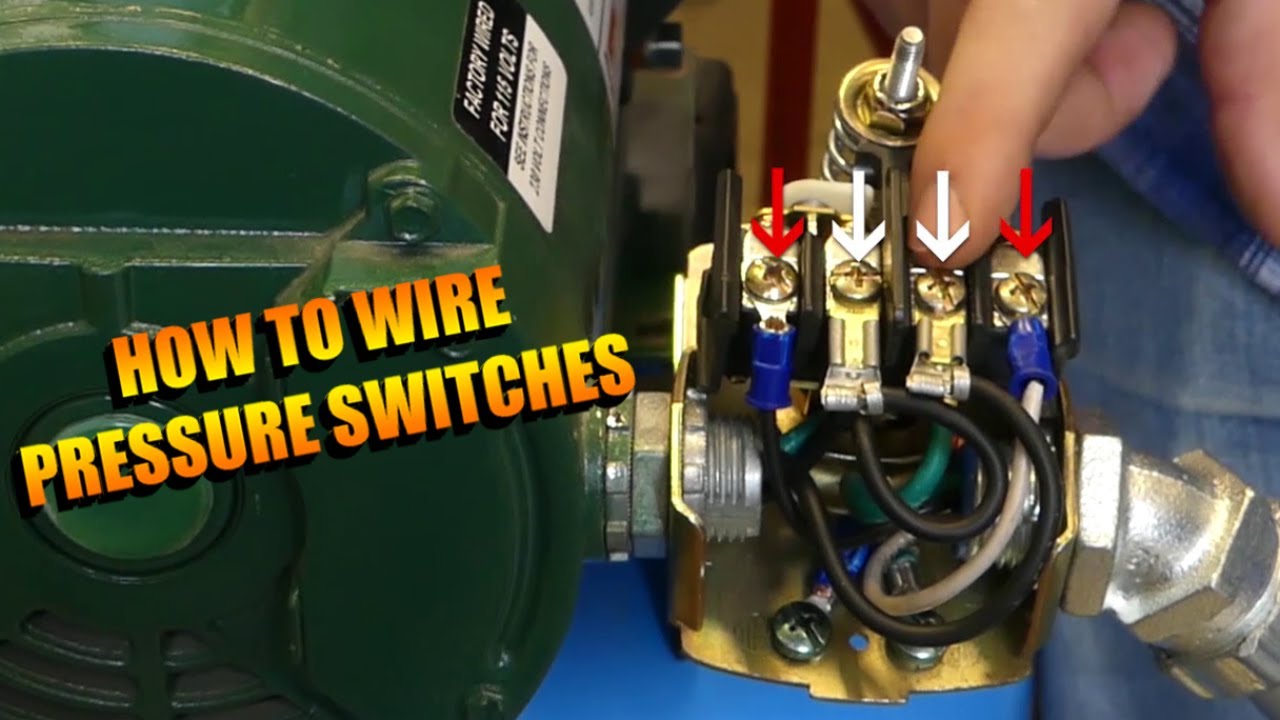

Then screw in a new one and tighten it down. Your well pump gets its marching orders from the switch mounted on. Wires coming down from pumptec and then continue down through the bottom of the box go to the well. In the most basic way to say it float switches detect water levels and provide a signal to a computer to tell it what to do once the. Mount on float switch it is a necessity that you need to mount on your device using some fixing ways of the cable on the well or the tank. Black sheathed wire coming in from the bottom.

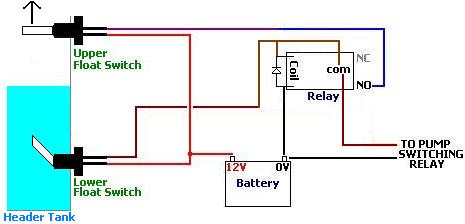

Now there is no load on the float switch as i will be using a contactor to switch the pump locally. Also in a multi point float switch the process could go even further by programming your automatic pump to stop after the water level has reached the fill stop probe. In a multi point float switch a low alarm could trigger the led light to turn on and send a signal to turn on an automatic water pump to refill the water back to the preprogrammed water level. I have had a look on the web and cant see any instructions on how to do it using a four core does anyone have any advice or diagrampicture or link they can send me on this. Then unscrew the conduit locking ring and pull the wires and conduit out of the switch. For most of us this wont suffice since most well pumps are 1 hp or larger.

This is perfectly normal and the correct way to do it once these connections are made you are ready to turn the power. I have been asked to fot a float switch to a pump not a problem but the distance is 525m. I see no reason not as there is no load to take into account. Label each wire with tape. The other leg will connect to the hot wire from the pump. A job that has got me second guessing my calculations.

Yesterday at 504 pm 2 i assume it controls the contactor so there must be load on it and. Sump alarm 2359 and 2368 series 3 wire float switches are rated for direct control of pumps up to 12 hp or 13 amps at 120 or 240 vac for non continuous operation of the pump. One leg of the float switch will connect to the hot wire from the panel. With the cable being so long it affects the price alot should it require a larger cable. I have been asked to fot a float switch to a pump not a problem but the distance is 525m. Now you are left with the hot wire from the panel and the hot wire from the pump.

So i have previously installed float switch on previous pump worked which worked perfect. The diagram below details the use of either a. The black lead is connecting to the left side coil contact and the white lead is connecting to the bottom right terminal. The float switch has two legs. Now there is no load on the float switch as i will be using a contactor to switch the pump locally. I have now got a new pump cut the wire to the pump to install the excising float switch i have but on cutting the pump wire noticed it has four core wire rather than the three core previous.