Liquid concentrate is used at 05 to 3 by volume in water at 65 to 90f. The finish has outstanding resistance to salt spray greatly surpasses the normal 96 hour salt spray resistance specified for yellow chromates on zinc.

Zinc Barrel Plating Jackson Michigan Elm Plating Co

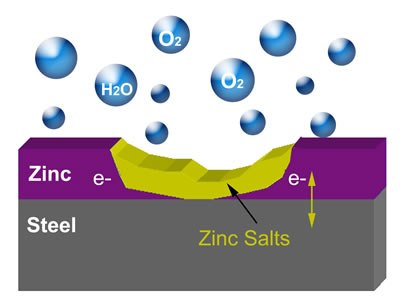

Zinc chromate plating at home. Zinc plating is the process of covering steel with a layer of zinc chromate to protect the steel from corrosion. It is desirable to have multiple anodes surrounding the work to help keep the plating thickness uniform. For professional zinc plating of your steel materials at competitive prices you can trust the experts at industrial anodizing co. The part must be completely submerged in the plating solution. Clear zinc plating clear zinc plating refers to a colorless chromate conversion coating that is applied over zinc as part of the post plating process. High salt spray clear a high performance trivalent passivate that can provide over 100 hours of corrosion resistance to white salts per astm b 117 to electroplated zinc.

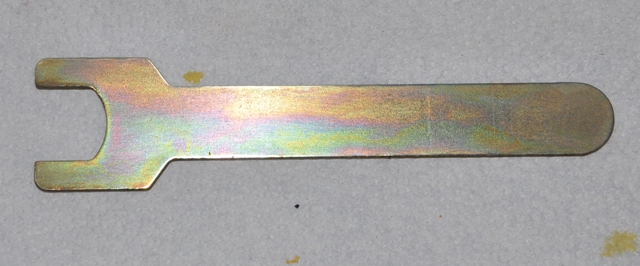

The zinc anodes were connected to the positive power source terminal and item to be plated is the cathode and connected to the negative terminal. Free quotes are available. It includes a layer of zinc applied to a parts surface followed by black chromate applied over the zinc. Next install the copper pipe hanger cathode on top of the bucket and hang your part on the wire attached to the hanger. The yellow chromate is a yellowbronze iridescent finish on plated cadmium and zinc. Assemble the zinc anodes into the plating solution bucket as shown and attach the wire s from the zinc anodes to the positive side of the dc power supply.

This finish gives the part surface a silver appearance with a slight blue tint. Black chromate a trivalent black chromate conversion coating for zinc that provides 120 hours to white corrosion when used in conjunction with a sealer. Two zinc anodes were clamped to opposite sides of the tank with wooden clothes pins. In place of cadmium caswell has developed a safer zinc chromate dipping solution that produces a golden iridescent finish on fresh zinc plating. Black zinc plating refers to the color of the chromate that is applied during the post plating process. It is possible to produce a finish resembling gold cad at home however using the copy cad kit developed and sold by caswell of lyons new york.

Black zinc is commonly specified for its dark appearance and protective properties. Zinc plating can be applied in clear trivalent or yellow hexavalent. Clear chromate or passivate protects the zinc layer and offers additional protection against corrosion.