Failure analysis shows that up to 85 percent of all gasket failures are due to faulty user installation though it is important to note that with proper training and installation procedures most of these failures are preventable. Do not force the pump on by striking the pump shaft.

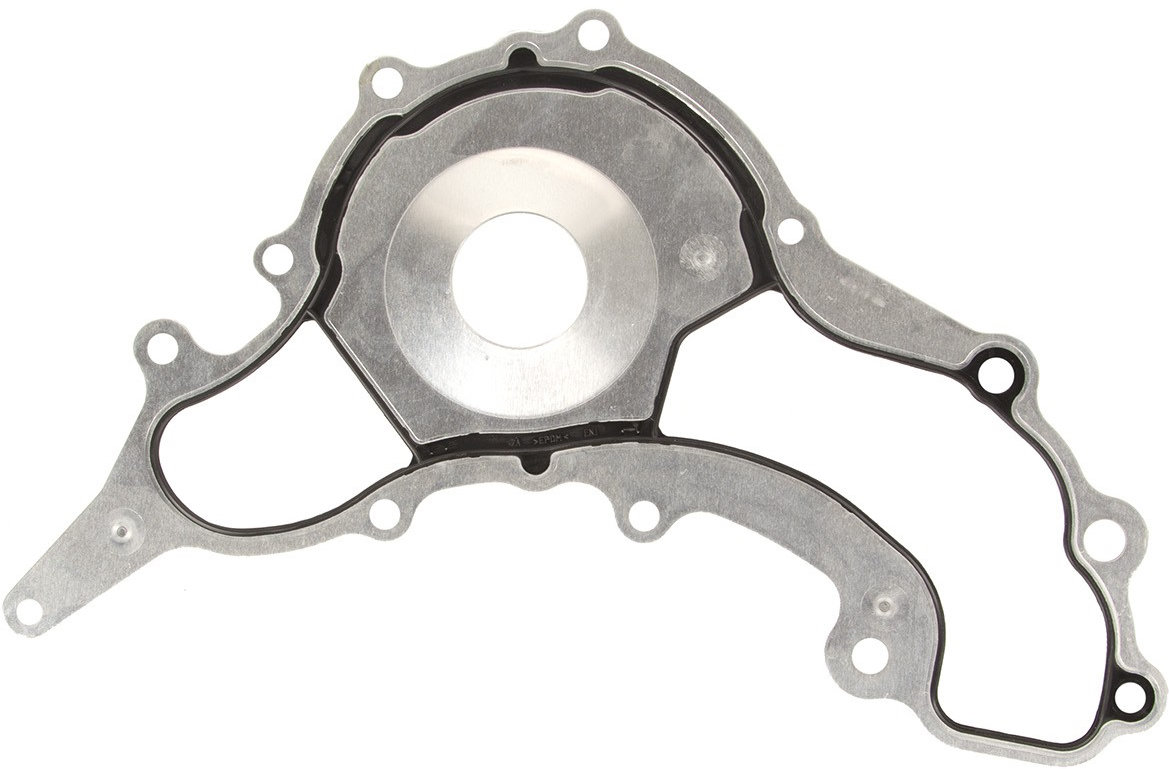

Fel Pro 35747 Water Pump Gasket Set

Water pump gasket installation. Dont put it on too thick just enough to hold the gasket in place on the block or on the pump. Primarily you want to install these components to set the oil pan and gasket for the final installation. Old gaskets and seals should be replaced by new ones. Improper installation will. An improper seating damaged seal or misaligned gasket can mean the water pump is not operating efficiently or worse is under undue stress from misalignment. Asme pcc 1 is a post construction guideline for pressure boundary.

Install the new water pump. For this build i used a dorman aluminum timing cover and ford racing water pump. Without the gasket the coolant flowing between the water pump and the engine block would undoubtedly leak out. Gasket failures can be problematic causing unwanted downtime revenue loss and safety concerns. It will do the same job and work just as well. Carefully follow installation instructions.

Should leave you in good stead. Use the gasket and put the gasket maker on either side of it. In the past it was not uncommon to coat a gasket with sealers or adhesives before installing it. The water pump gasket is a simple sheet comprised of gasket paper rubber silicone metal felt and fiberglass or plastic polymer. It fills the gap between the engine and the water pump in your vehicle. Proper installation is the key to long service life as installation practices are changing rapidly as gasket designs advance.

Today fel pro offers many gasket designs with advanced leak sealing technologies built directly into the gasket.