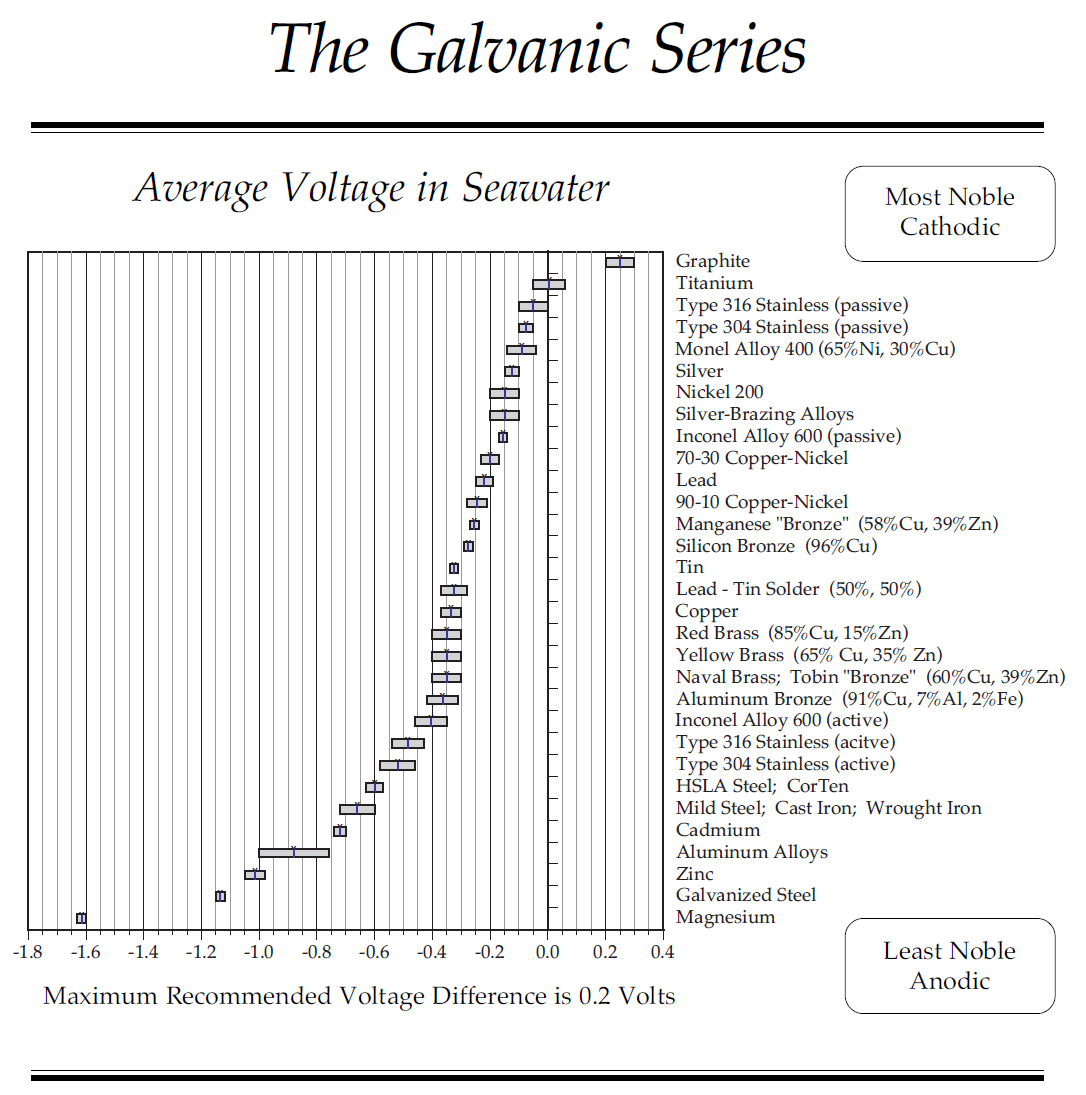

Blind rivets are usually categorized by the material of the rivet and then the material of the mandrel. If steel pop rivets are used you will have a rust problem in that area long before there would be a problem using aluminium pop rivets.

1 16 Dia 1 8 Long Aluminum Rivet 50pcs

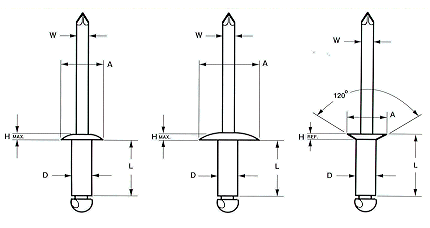

Steel vs aluminum rivets. Rivets are specified by the material of the rivet and the mandrel in that order. These are just typical pop or blind rivets in aluminum. This particular rivet is steel and steel. It will seat the rivets much better than a hand powered one and they are not too expensive. I replaced them with hardware store aluminum rivets. This is what they call a blind rivet.

I would use steel rivets on steel and aluminum rivets on aluminum because of the dissimilar metals. Aluminumsteel aluminum rivet with steel mandrel. If you use stainless or monel i suggest getting a pneumatic pop blind rivet gun. If you use aluminum rivets with steel mandrels it is likely they will outlast your ownership of the coach. It sounds like the steel is what is actually being riveted on. These fasteners typically come in steel stainless steel nickel copper alloy and other grades of aluminum.

Often steel mandrels are specified with aluminum or stainless steel rivets because the steel mandrels are less expensive than matching aluminum or stainless mandrels. Even if you need to use aluminum rivets in situation like this where one of the materials being joined is aluminum you at least use one with a steel manderal. The mandrel is steel and the hat is steel. These three are aluminum rivets. For example you might see aluminumsteel which means an aluminum rivet with a steel mandrel. This is a structural rivet.

Yes but aluminum will corrode much faster in contact with steel because of galvanic corrosion. You never use aluminumaluminum rivets in stress bearing applications. Thu dec 16 2004 309 pm location. Monel rivets are expensive unless you buy them by the thousands. Monel does not react with aluminum so you do not have to worry about isolating the rivets. However if this is in a dry indoor location where there is no corrosion the go ahead and use them.

So if you are using this in a wet or corrosive environment then the rivets wont last long. We also have what we call a white hat rivet with an aluminum mandrel. Pop rivets in my barth began deteriorating from galvanic corrosion at around 14 years of age because they fastened the aluminum skin to the steel framework. Dont get on to the roundabout if you dont know how to get off.