They are used to prevent gas and fluid leaks in static and dynamic applications and are manufactured from various types of elastomers. Nitrile rubber nbr hnbr hsn buna n.

Vijay Rubber Products Nbr And Viton Rubber O Ring Id

O ring material nbr. Nitrile butadiene rubber nbr is a family of unsaturated copolymers of 2 propenenitrile and various butadiene monomers 12 butadiene and 13 butadiene. The term buna n is really not much more specific than the term steel. Hnbr o ring meets higher temperatures than standard nbr the hnbr o ring has recently been developed to meet higher temperatures than standard nbr while retaining resistance to petroleum based oils. For the purposes of this article we will focus on just three common rubber types found in o rings and similar automotive seals. The guide includes generalized recommended o ring mateiral uses and non recommended uses with typical material mechanical properties. Note that each type is actually a family of rubber compounds.

Buna n o rings also referred to as nbr o rings and nitrile o rings are the most widely used o ring material in the word because of low cost good mechanical performance with resistance to water most basic oils lubricants and some fuels many pneumatic hydraulic systems and the default choice for basic applications. This popular o ring material family comparison shows basic rubber material family properties and performance plastic properties. The hnbr o ring has a temperature range from 30c to 150c 20f to 302f. As the nbr content increases resistance to petroleum base oils and hydrocarbon fuels increases but low temperature flexibility decreases. Acrylonitrile content varies in commercial products from 18 to 50. A common material for o rings because of its good mechanical properties its resistance to lubricants and greases and its relatively low cost.

The physical and chemical resistance properties of nbr materials are determined by the acrylonitrile acn content of the base polymer. Acrylonitrile content varies in commercial products from 18 to 50. As the nbr content increases resistance to petroleum base oils and hydrocarbon fuels increases but low temperature flexibility decreases. Hnbr o ring has excellent resistance to oils and chemicals. O ring material family chemical compatibility temperature resistance and other properties all factor in to o ring material selection for an application. Nitrile rubber also known as nbr buna n and acrylonitrile butadiene rubber is a synthetic rubber copolymer of acrylonitrile acn and butadienetrade names include perbunan nipol krynac and europrene.

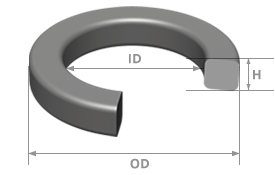

Nbr nitrile nbr nitrile chemically is a copolymer of butadiene and acrylonitrile. Nbr nitrile chemically is a copolymer of butadiene and acrylonitrile. O ring materials o rings are mechanical gaskets with a round cross section. Exposing rubber o ring materials to multiple chemicals and compounding application factors like temperature pressure and gland design can result in significantly different performance. Some of the common types of o ring materials include ptfe nitrile buna neoprene epdm rubber and fluorocarbon viton. Buna n viton and epdm.

Low content ensures good flexibility at low temperatures but offers limited resistance to oils and fuels. Basic o ring chemical resistance compatibility information is based on isolated generic o ring material testing in optimal conditions at room temperature and pressure.