Available at many hvac or refrigeration supply houses. How tight do you have to tighten national pipe thread.

Pipe Thread Types And Designations Pdf Free Download

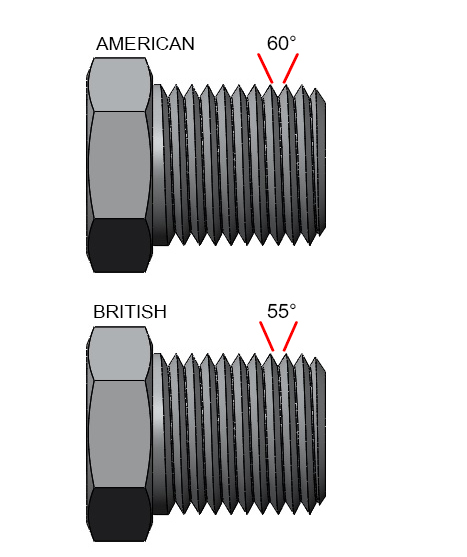

How many turns npt thread. Rule of thumb. The angle between the sides of the thread is 60 deg. 14 18 npt lh for pressure tight joints it is intended that taper pipe threads be made up wrench tight with a sealant. Fluids piping and hydraulic design data. Tfft assembly turns from finger tight with pipe thread sealant or teflon tape applied. Continue to turn the male pipe fitting in a clockwise direction until you can no longer do so approximately two to four full revolutions depending on the size and type of fitting.

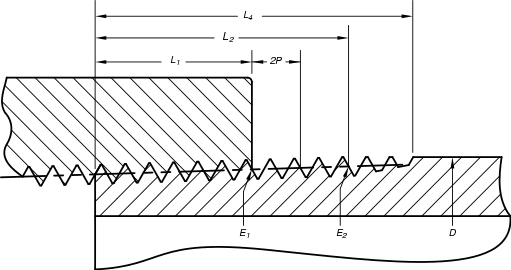

For left hand threads include lh to the designation. Your seal is made at the thread root with the sealant so overtightening will not fix a leak. Any number outside of this range may indicate either under or over tightening of the joint or out of tolerance threads. Larger fittings will turn more easily than smaller diameter fittings. Npt thread taper angle 116 taper 1 deg. Npt thread calculator for npt thread dimensions according to ansiasme b1201 standard.

Tighten fitting by hand and then turn it 2 turns with a wrench until it reaches the desire torque. Pipe thread installation torque table chart. The nominal pipe size number of threads per inch and the thread series symbol in sequence. The angle between the taper and the center axis of the pipe is 1 47 24 17899. All 18 through 2 npt threads theoretically are 7 turns total. If i did not have at least 4 threads engaged on 18 or 14 npt fittings i would remove clean use thread cutting oil and re tap the fitting.

Brass and steel pipe thread npt installation procedure and torque specification table and chart. More turns will put to much pressure on the fitting and may crack it and cause a leak. National standard taper pipe threads size npt chart includes both external and internal pipe thread data. The taper rate for all npt threads is 116 34 inch per foot measured by the change of diameter of the pipe thread over distance. You should have between 35 and 6 engaged threads. If you were to take the cross section of a npt threaded end you would see that the bottoms of the threads arent on a cylinder but a cone.

47 min 075 inft. 3 5 turns for hand tight then 2 3 turns power makeup. I tighten by feel. This is the taper which is 116 inch per inch which is equivalent to 34 inch per foot. Step 4 fit the pipe wrench onto the outside of the male pipe fitting. Engagement tighten 2 full turns for sizes up to 1 inch for npt thread fittings.

They should be hand tightened and then another 1 or 2 turns but no more. So in the real world unless working to nrc specs 5 8 turns total will do.