Air leaking out of a breather indicates ring leakage. This procedure is different and usually more accurate than a compression test which just measures the pressure inside a cylinder.

What S The Difference Between Compression And Leak Down Testing

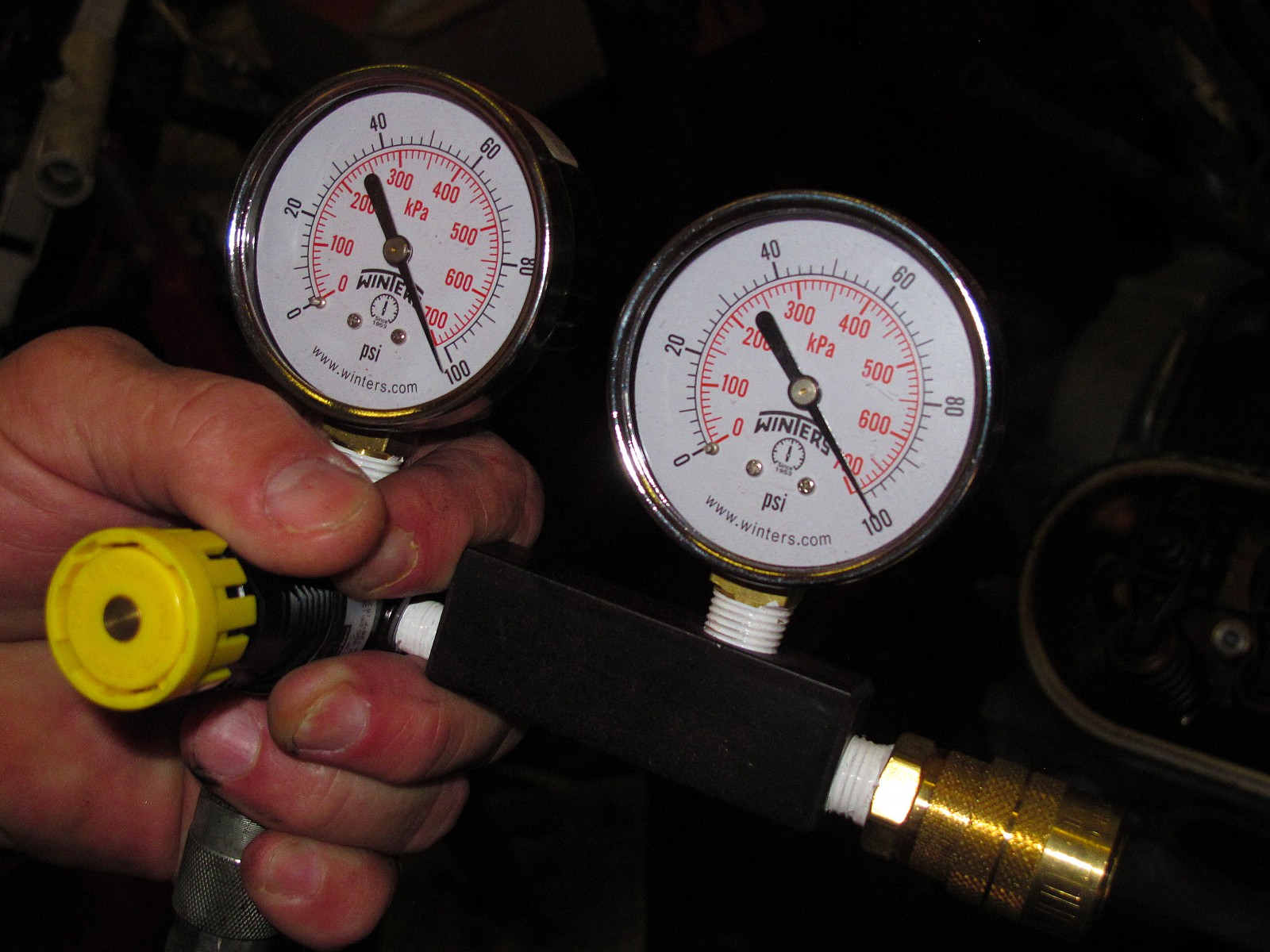

Leak down test results. A cylinder leak down test will indicate the area of the combustion chamber needing attention. A cylinder leakage test is performed when a cylinder produces low compression and compressed air is available. The first set of results is right there in your hand displayed on the right hand dial on the leak down test tool. Air leaking out of the exhaust system indicates a leaking exhaust valve. A leak down test is one way a mechanic can find whether an engine has an internal problem instead of something external like a bad spark plug. Air leaking out of the carb indicates a leaking intake valve.

They both test the sealing ability of the combustion chamber but the leak down can tell you how much is leaking and where its going. So a compression test measures how well your engines cylinders are sealing. The dial will be laid out with percentages usually ranging from 0 to 100. Step 1. First of all do no expect a 0 reading. Remove the spark plugs and rotate the engine to put the cylinder to be tested at tdc.

See all 14 photos engine compression atmospheric pressure at sea. A cylinder leak down or cylinder leakage test is actually similar to a compression test. There are precious few engines with the build quality and strength to withhold 100 of air pressure. Even for normally aspirated engines respectable leakage numbers would be anywhere from 8 to 12 percent with a variation between cylinders of 4 to 5 percent but its possible the variation could. Leakdown testing is by far the best method for checking an engines basic condition. Doing a cylinder leak down test can tell you more about your engine than you think.

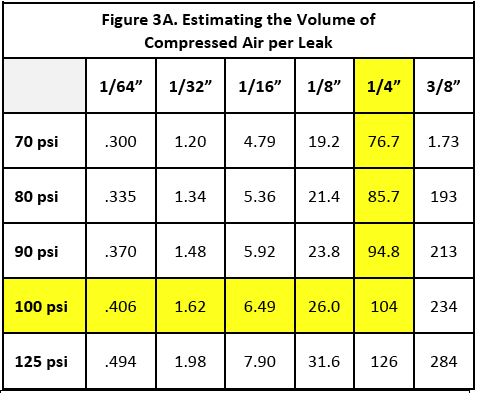

Consequently good cylinder leakdown readings should be below 5 8. The cylinder leak down test reading is expressed in a percentage. Put the vehicle in gear and. Record leakage percentage for the cylinder. The tester then measures the volume of air needed to maintain a predetermined pressure in the cylinder. Then using a similar type of connector as the compression test we fill the cylinder with pressure.

Figure out which spark plug adapter works best and connect the gauge into the hole. Browse recommended tools supplies for this build. Also a cylinder leak down test can pinpoint issues in specific areas that other tests can not. A leak down test can tell you quite a bit more about an engines mechanical health than a compression test can. A compression test is to determine how much pressure the engine makes and a leakdown test measures its ability to hold pressure. The leak down test measures pressure loss inside a cylinder.