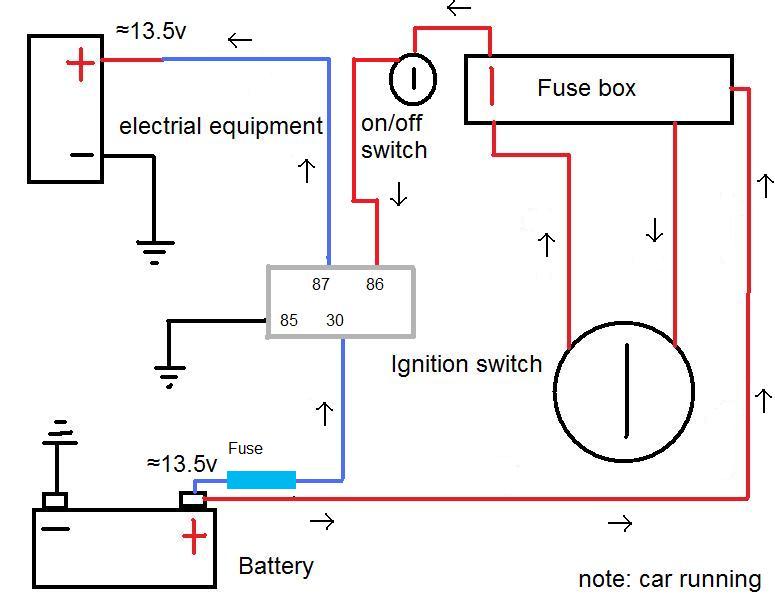

This is how the factory switches devices like the fuel pump. Then connect the other wire from the switch to the remaining end of the cut off hot wire to allow electricity to flow to the fuel pump when the kill switch is in the on position.

Thesamba Com Beetle Late Model Super 1968 Up View

How to wire electric fuel pump to toggle switch. Check out the wire voltage drop calculator here to help with selecting the right gauge wire for relays and related switches 16 or 18 gauge would be ok. Never open your fuel pump assembly to install a fuel pump kill switch. Wire the oil pressure switchs s terminal to the ignition cranking start circuit to provide fuel pump pressure during engine cranking andor via a dash mounted toggle switch to prime empty. Electric fuel pump wiring. Although you can use electrical quick connectors its recommended that you solder your connections. Quick informative video on hot wiring the fuel pump on a 3000gt vr4.

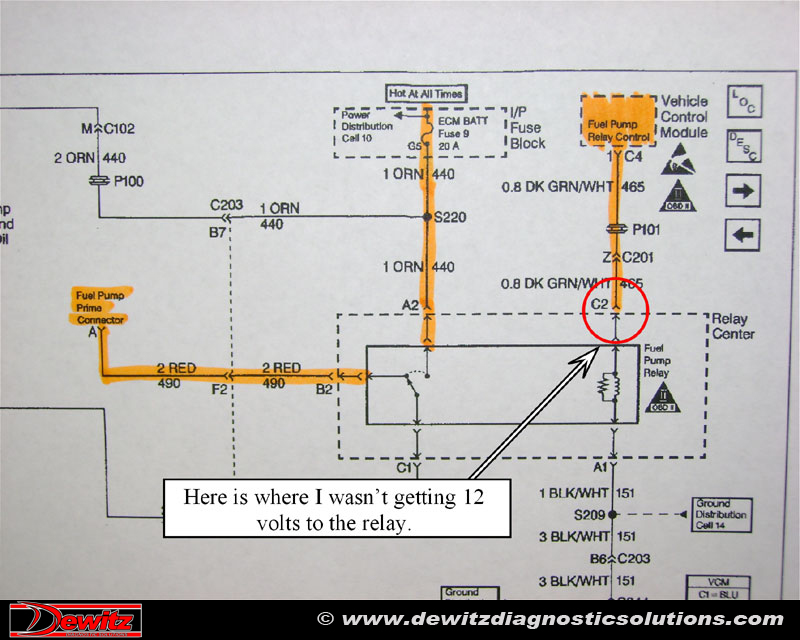

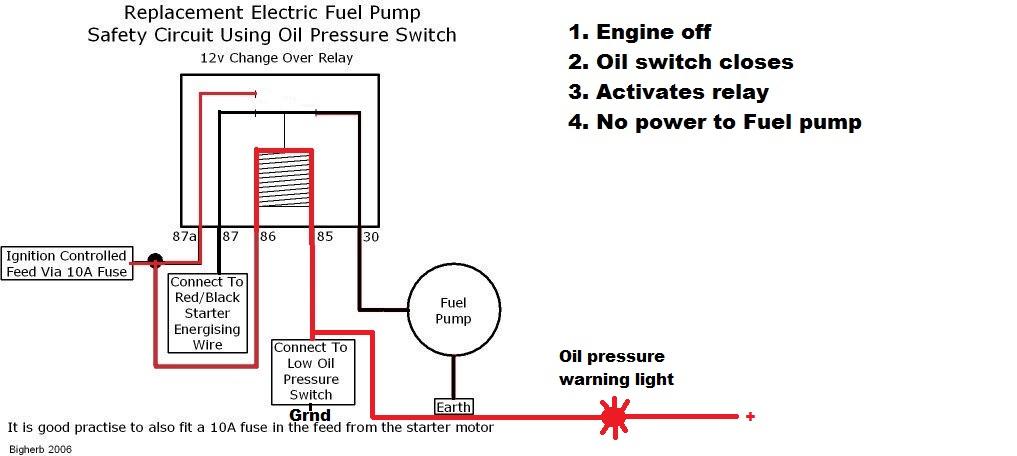

One wire goes to the pump one to the start circuit and the other to the ignition circuit. When the oil pressure comes up the switch connects ign to pump for normal running. Use a butt connector to connect one of the wires from the switch to the hot wire you just cut routing the energy flow from the electrical system to the switch. Basic operation ignition is turned on but no fuel pump due to the normally open pressure switch. The fuel pump ground should be the same gauge as the positive lead if not obvious. It is common to wire an electric fuel pump directly to the ignition switch or to a two way toggle.

You can jump pole 30 and 86 together and run the wire from from pole 85 to the toggle switch and a wire from the other side of the toggle switch to ground. More typical for diyers would be to ground pole 85 and run another 12v lead to the other pole of the toggle switch. Once you have wired in your fuel pump kill switch double check your connections to make sure that you dont run the risk of your pump turning off on its own. The method shown here has proven to be beneficial for both safety and to help prevent flooding caused from hot under hood temperatures. So when there is no oil pressure the switch connects start to pump and as soon as you start cranking it runs the pump.