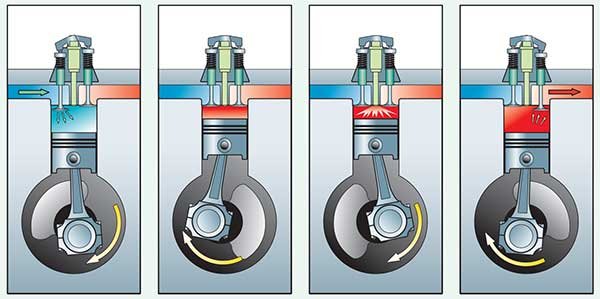

Most people start with cylinder number one and follow the engines firing order. Make sure the cylinder is at tdc of the compression stroke so all the valves are closed and attach the leakdown tester to the cylinder head.

Checking Compression On An Outboard Engine Boatus Magazine

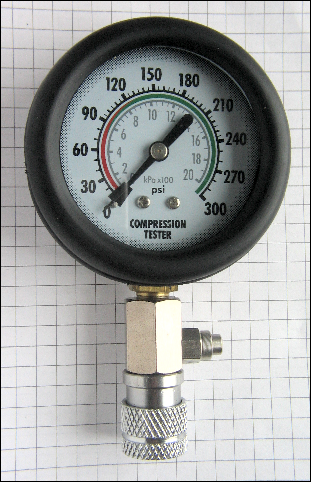

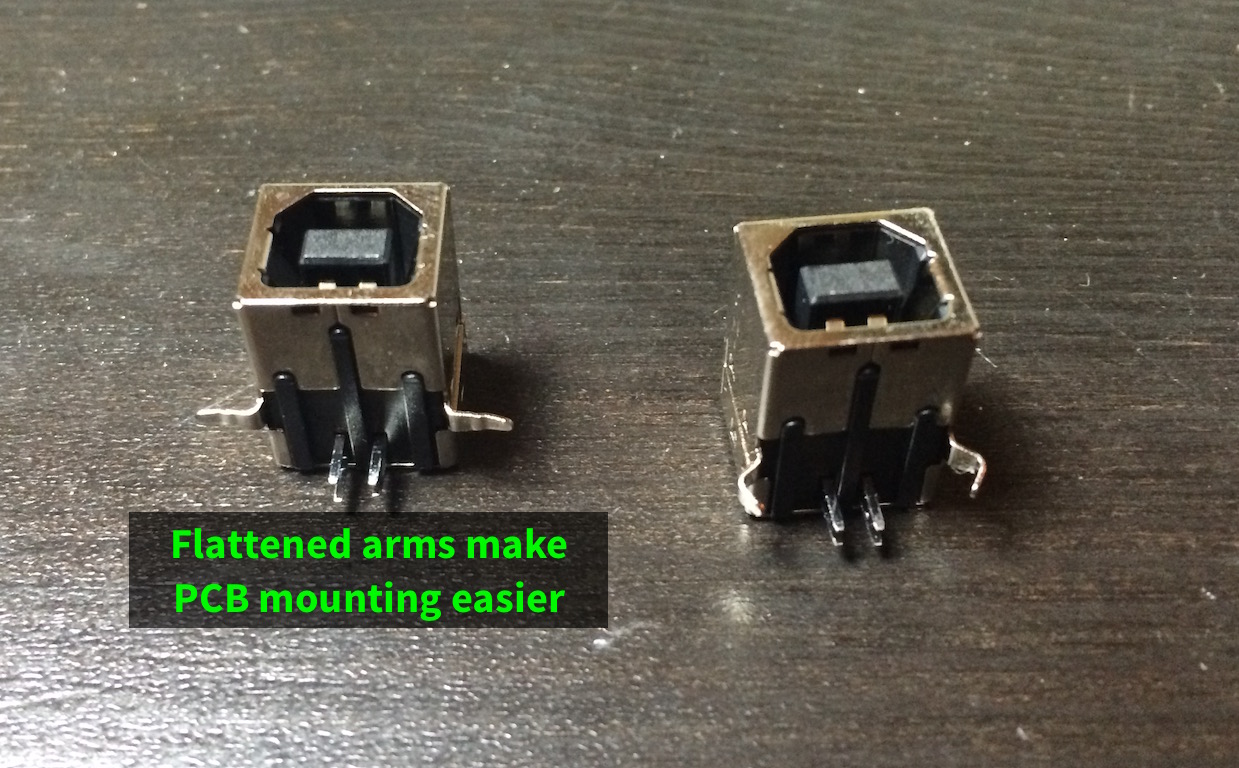

How to make a compression tester. Compressed air 80 to 90 psi is then fed into the cylinder. A threaded coupling is screwed into a spark plug hole. Thanks everyone for watching. Look down on the engine to figure out which. Using a few air fittings i made an adapter to convert a compression tester into a cylinder leak down tester. Compression tester turned leak down tester duration.

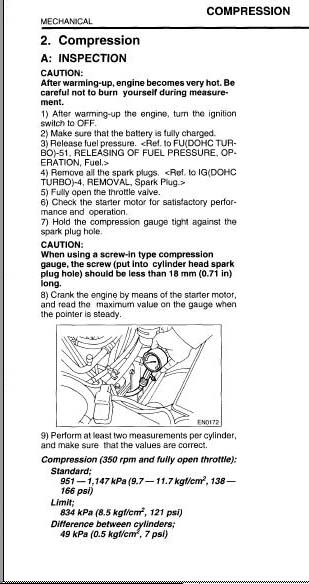

Performing the test 1. You will be able to hear the cranking speed slow. All engines leak somewhat so even on a healthy engine the gauge will drop down to 90 psi 10 leakage or so. Take an old spark plug to the hardware store and locate a male coupling that is the same size as the spark. How to make a pressure test fitting from a spark plug for compression testing or leak down testing. Note how fast the compression increases and write down the highest reading.

How to make a compression test gauge. Crank the engine at least 4 times to. The crankshaft is then turned so that each piston is at top dead centre. Connect the compression gauge to the opposite end of the hose. Take the compression gauge and screw it onto one end of the hydraulic hose. As the tested cylinder comes up on its compression stroke.

It seems to work pretty good. If youre testing a diesel engine make sure youre. If the hose does not fit check the hardware store for a. If it drops a large amount then you have a leak from chipped valves or a bad headgasket etc. Put the compression test adapter into the engines first cylinder. First of all connect the tester to a cylinder and turn the engine over 6 to 8 compression strokes.