Fittings for hard tubing can be simple push in hd fitting type. An fittings aka army navy fittings are a high quality way to plumb the fluid and even some air lines on your.

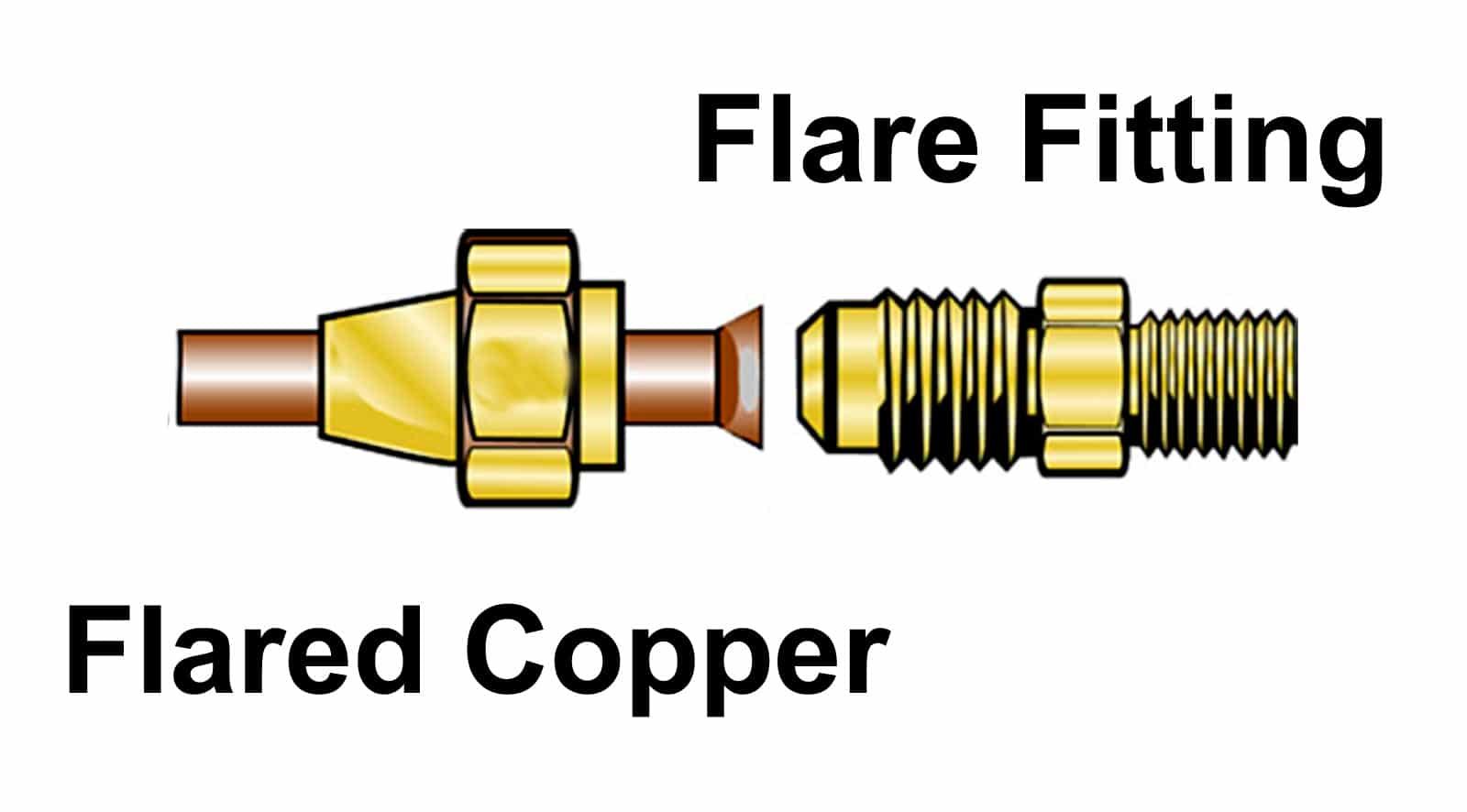

How To Flare Copper The Different Tools Techniques And Tips

How to install an fittings to hard line. In this video we go over the basics and some important information about an fittings. Dicks 4x4 garage 18774 views. I purchased the nos tubing bender from nitrous outlet complete nitrous kits nitrous accessories and it is part nos 15991. I used the tubing bender shown earlier and also had to use my nos tubing bender for one of the bends. Aeroflow aluminium stainless hardline series hose installation duration. Hand tight will never be tight enough for a hardline connector so make sure you use the proper tools and tighten the connector.

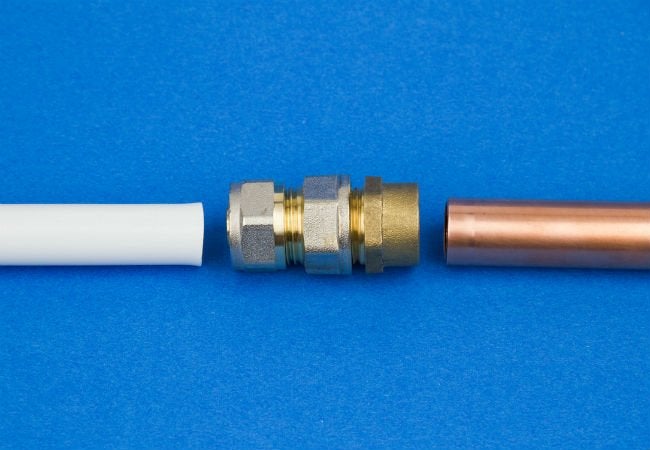

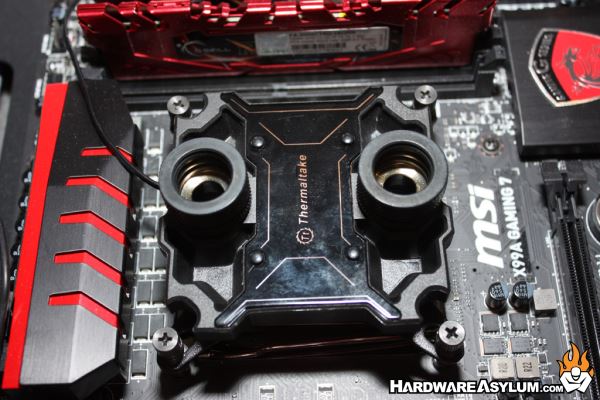

Same as for the soft tubing and other water cooling components you cannot pick up just any random hard tubes from the flea market. Hard tube an adapters connect 38 in. Tubing to an fittings with ease. Tube to 8 an male or female end. Simply slide tubing into tube nut install ferrule attach tube end. I ended up with 2 sticks left over but i think that this was a reasonable amount for my build but its better to be safe than sorry.

Petg and i used 2 packs of 4 sticks. Tighten connector fully when installing on the cable. On my civic the stock fuel feel line is a 38 hard line going up to the fuel filter which i have already cut off to clean up the bay a little. Cutting braided hose and installing an fittings duration. What i was thinking was to use this jegs 110551 jegs hard line an adapter fittings on the end of my hard line. There is a trick to it.

The hd fitting has two o rings on the inside you just have to push the tube into the fitting and airtight seal is made. Except im not sure what material the ferrule is. Tube to 6 an male or female end and 12 in. You will need one fitting per connection. Converting a hard tube line such as a fuel line to a standard an fitting size. With a hose clamp on bare hose or the proper way with a tube sleeve a tube nut and an an fitting.

Worry no longer about flaring and splitting aluminum tubing to make connections. Then i had to bend a hard line to connect the master cylinder to the top fitting on the solenoid. I used compression fittings and some 90 rotary fittings to make it easier on bending. Going from hard lines to an fittings and hose can be done two ways. One of the most common mistakes when installing a hardline connector is not tightening it fully during the process of installing the connector onto the cable.