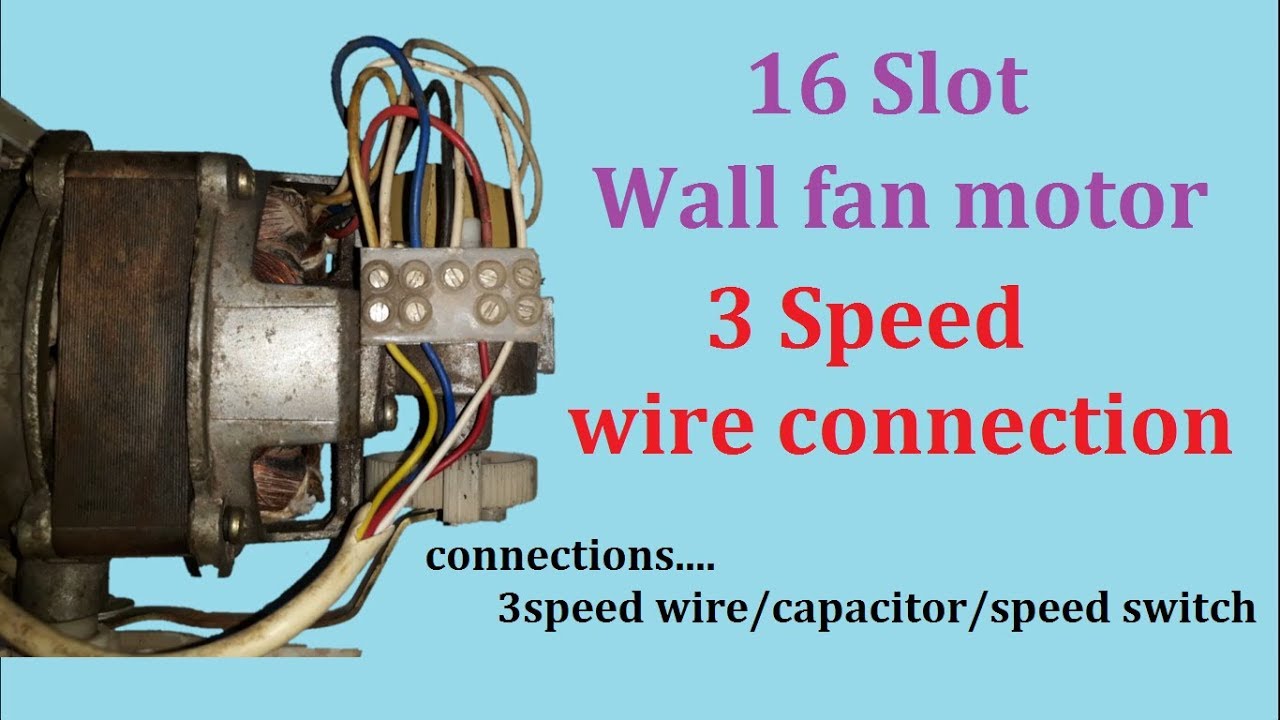

This enables one motor to be used for a number of different applications. Two speed motors use a switch oriented towards either high speed or low speed coil.

Iliving 18 In 3 Speed Wall Mount Outdoor Waterproof Fan

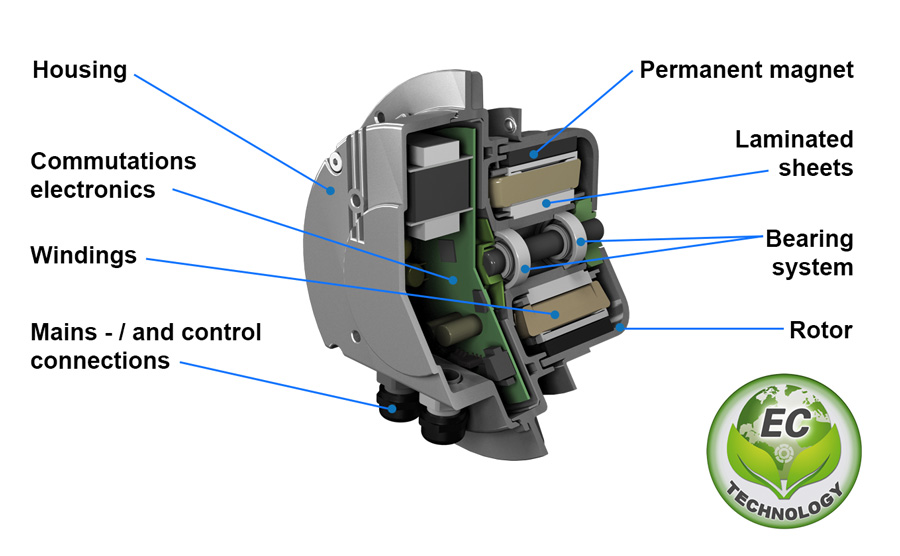

How does a 3 speed fan motor work. Knowing this you can begin to appreciate the versatility of multi speed motors in the field. Below is the circuit diagram of split phase induction motor in a ceiling fan clearly showing a capacitor connected in series with the starting winding auxiliary winding. You could use the above multi speed motor to replace single speed 13 hp 14 hp or. The fan motor will be an induction motor. Ask question asked 6 years 7 months ago. A three speed motor has three field windings and a rotor all in one housing.

Before go in details about why a capacitor is connected in series with the auxiliary winding let is know what will happen if there is no capacitor in a ceiling fan. How does a multi tap motor speed control work. For example if you have a 13 hp motor it generally would deliver 13 hp when connected to its high speed 14 hp at its middle speed tap and 16 hp on low speed. However proper safety procedures must be adhered to because any work with wiring or electricity can. When such a motor is driving a fan a special case exists in that the torque required by the load drops rapidly with rotational speed. Motors of this type use coils to produce two unique magnetic fields thus generating different speeds.

Solid state controls are generally equipped in fans with controls that have predetermined settings such as low medium and high. Solid state controls change the level of power in the fan motor to control the speed of the fan. My fan motor has 5 wires with blue brown resistance 60 ohms and yellow red gray resistances of 29 96 and 120 yellow gray. The speed switch in ceiling fans appear to have some not straightforward logic in it. For instance when you switch from medium to high on a solid state fan the speed control mechanism increases the power of the motor. Each field winding is designed to spin the rotor at a different speed.

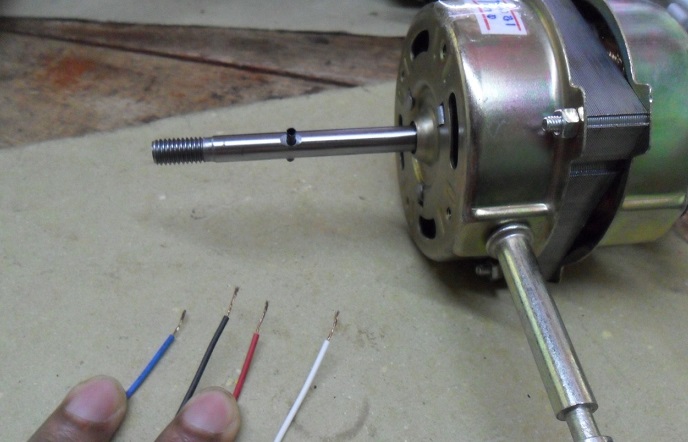

To circulate air more efficiently most box fans are equipped with a three speed motor that provides three different speed settings allowing the user to customize the blast of air to the size of the room. If you are trying to properly rewire or create a two speed motor the process is fairly straightforward. A three speed motor usually has four wires the three speed wires and the common wire. I think the truth table on my switch is. The torque of of an induction motor drop when you feed it from a lower voltage. A capacitor receives 100 percent of the power supplied from a power.

L123 i think my fan might take the hot in on 1 and feed the reversing coil with the l. Capacitors capacitors control the flow of power to a fan motor. As the machinist you are responsible for determining the speed at which youd like the motor to run. L1 maybe this is l12 d.