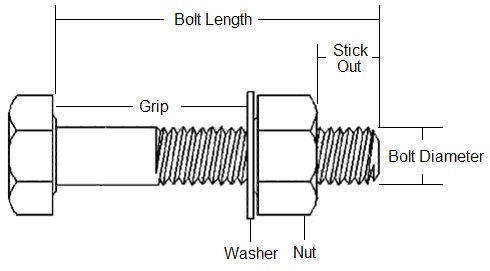

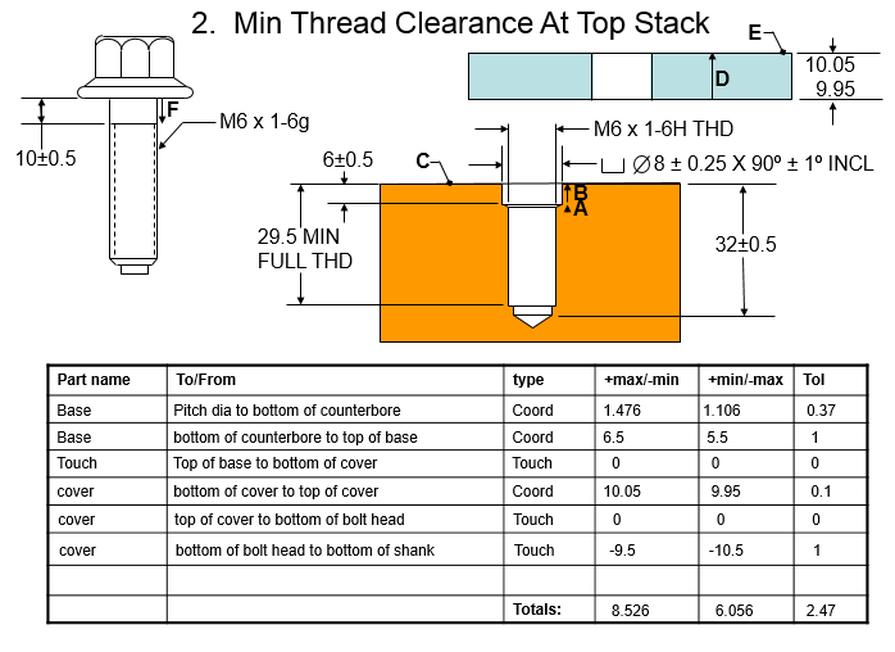

Add the length below to grip to determine bolt length required. Grip lengths are in 18 increments.

Bolt Stacks Dimensional Consulting

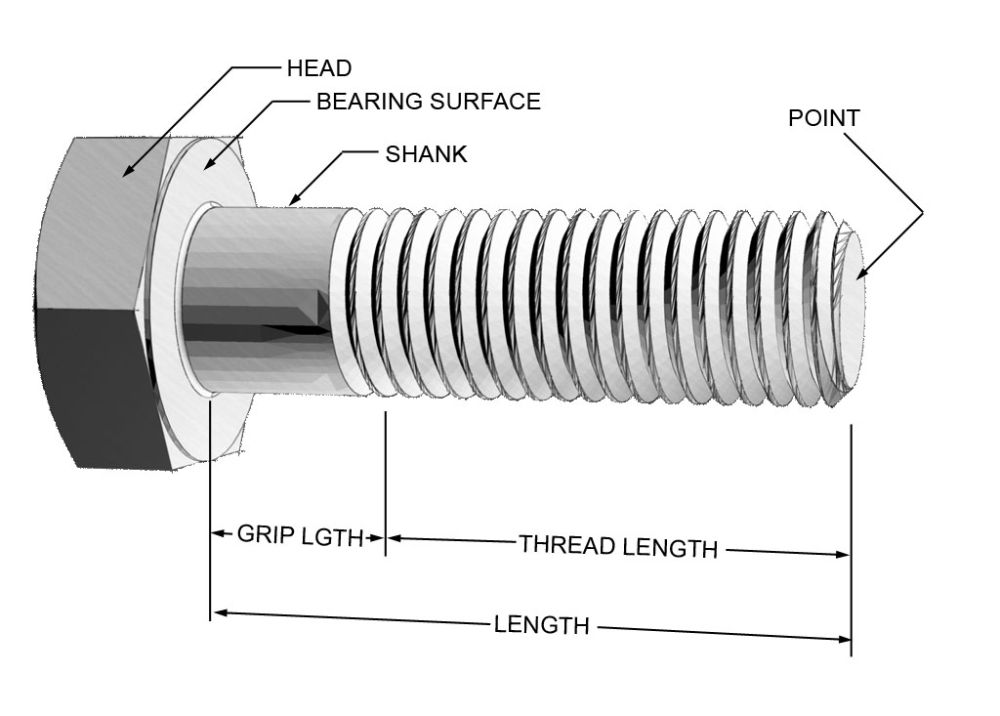

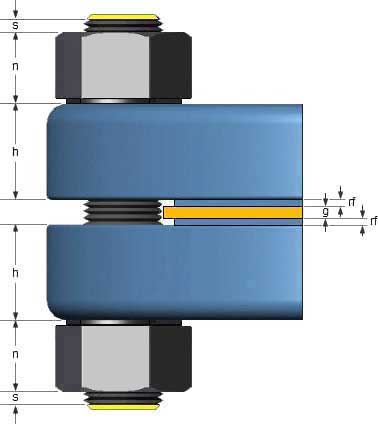

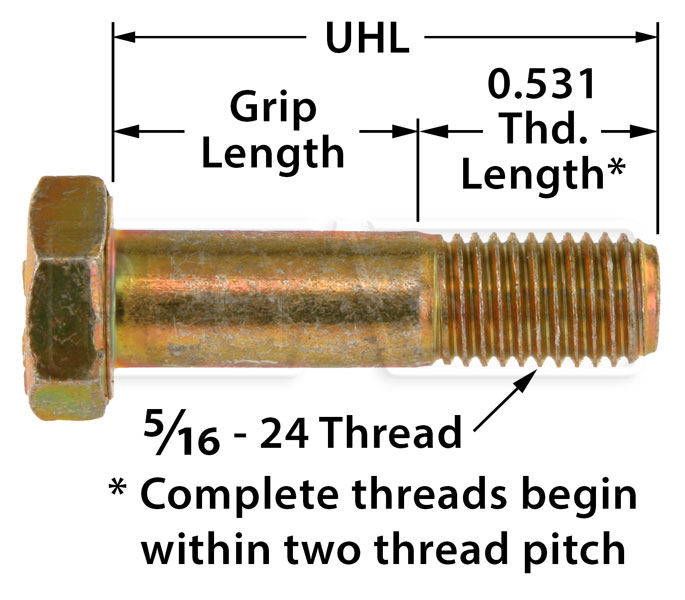

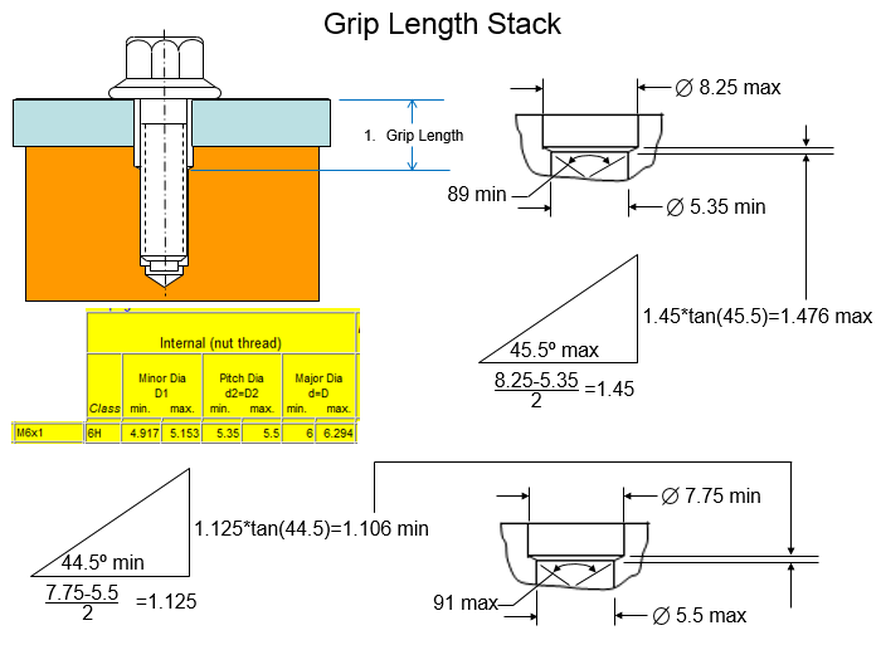

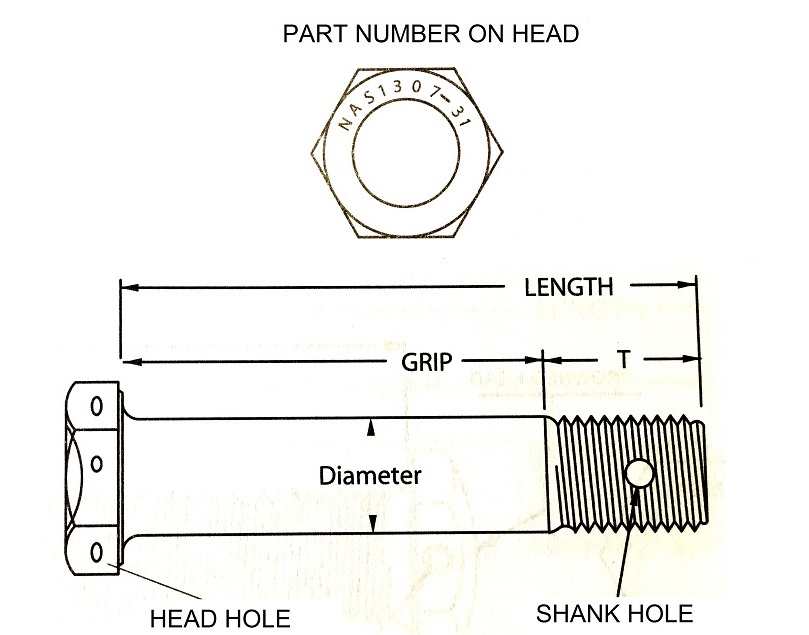

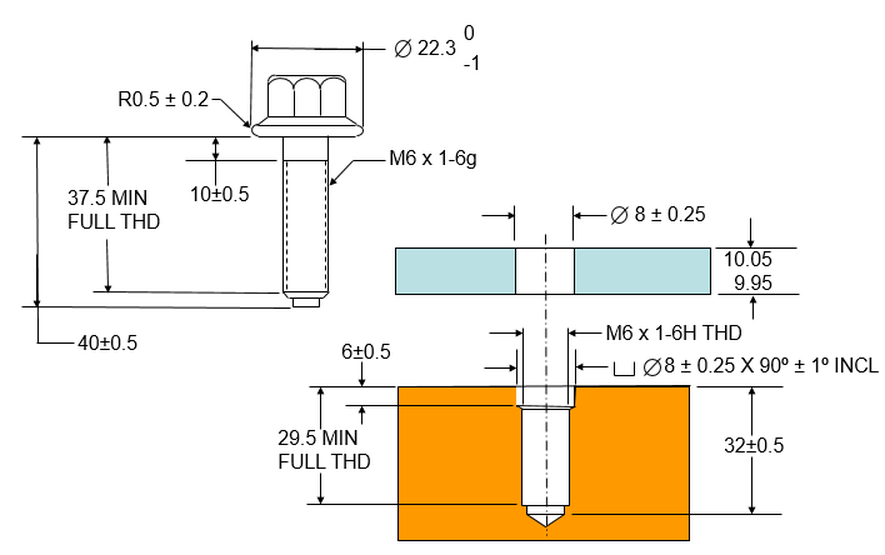

Grip length of bolt. From the bolt list select one of the bolt assemblies. This table can be used as a guide for bolt length estimation for our structural bolts. The unthreaded grip length should be chosen carefully to be around the same length as the thickness of the material and washers through which the bolt passes. Thats an important consideration when dealing with critical applications that involve a lot of vibration namely aircraft and racing. As shown in figure 5 2 the grip length should be approximately the same as the thickness of the material to be fastened. If beveled washers are used add an additional 516 inch to the no washer column for each bevel washer.

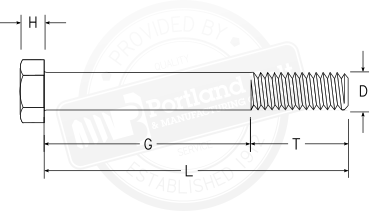

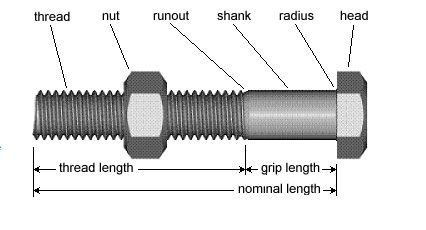

An960 washers are 116 thick 132 thick for the l version. Some bolts may vary from the standard thread length. No more than two turns of the thread should be within the hole. Grip length is the length of the unthreaded portion of a bolts shank. An bolt nomenclature follows this format. In addition if a bolt is too long or too short its grip will usually be the wrong length.

If your application falls between two grip lengths you can add one or two more washers to a bolt with the next longer grip. An overly long unthreaded length prevents the nut from being tightened down correctly. If you have any questions please contact our sales. On the parameters tab the grip length bolt length and projected lengths can be configured. To understand how advance steel automatically calculates the grip length lets see an example. Trying to make sense of all the different screw and bolt thread lengths can be a real challengeeven for the most knowledgeable of professionals.

If the grip is too short the threads of the bolt will extend into the bolt hole. As a rule no more than one thread should be within the bolt hole because vibrations can cause the threads to ream out the hole. An insufficient unthreaded length results in the threads extending into the hole and places the dowel shear load onto the threads which may cause fretting wear on the hole. Maximum grip length 116 increments nominal shank diameter 132 increments lubricant code see chart finish code see chart material strength level see chart head configuration see chart family type eddie bolt 2 with spline loktm recess prefix els 1 20 n n 8 6 y eddie pintm part number code example spline loktm recessnew numbering system.