This is where the greatest cylinder wear occurs. 3295 32.

5 Symptoms Of A Cracked Cylinder Head And Repair Cost

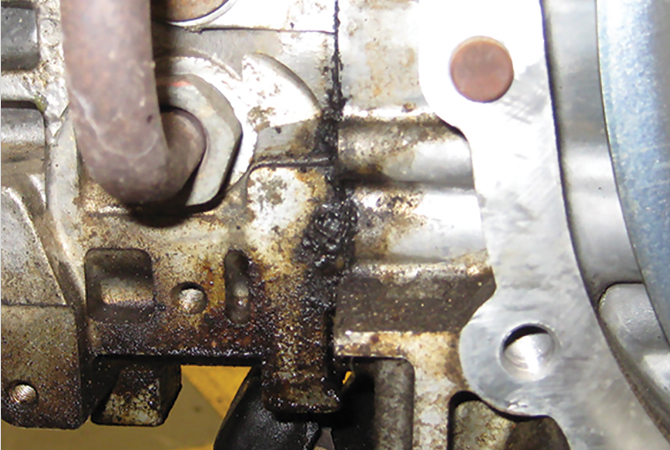

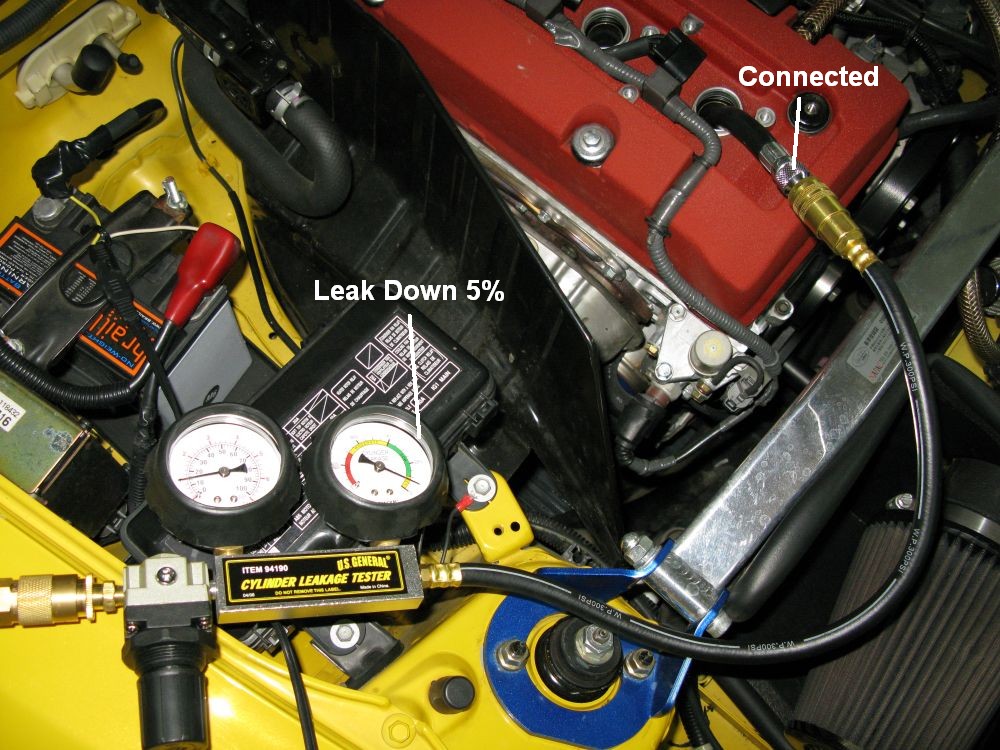

Cylinder head leak test. In contrast to the cylinder leak down test which measures how much pressure is lost in the engine. 30 out of 5 stars 2. If water leaks in and around the cylinder heads imagine how oil gas and air will escape into the wrong places under extreme pressure and temperature. A cylinder leak down or cylinder leakage test is actually similar to a compression test. Performed a cylinder leakage or leak down test after a cylinder balance and a cylinder pressure test has verified a problem with the cylinder. Cldt what are the results telling you.

However these kits can cost between 125 250. Be sure to blow out the excess water and spray wd 40 onto valve stems. The right hand dial will give a reading as a percentage. This is a tool that has a hand pump with a combination pressure gauge. 39 out of 5 stars 4. Passing this test automatically initiates the leak test cycle.

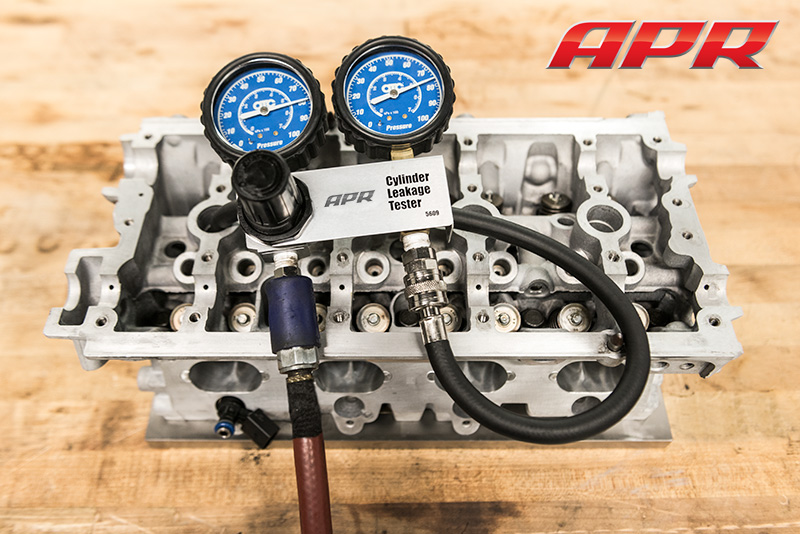

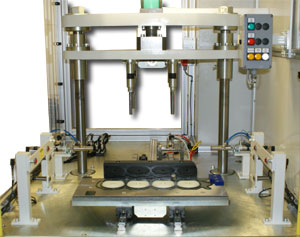

It does little good to measure leakage with the piston at. Niche cylinder head and base gasket kit set combo for 1996 2014 polaris sportsman scrambler worker 500 3089966 308537. The water cavity is pressurized with air and tested for a maximum leak rate of 5 sccm at 60 psig. So a compression test measures how well your engines cylinders are sealing. The system needs to process approximately 50. Both cylinder head internal water cavities are flow and leak tested.

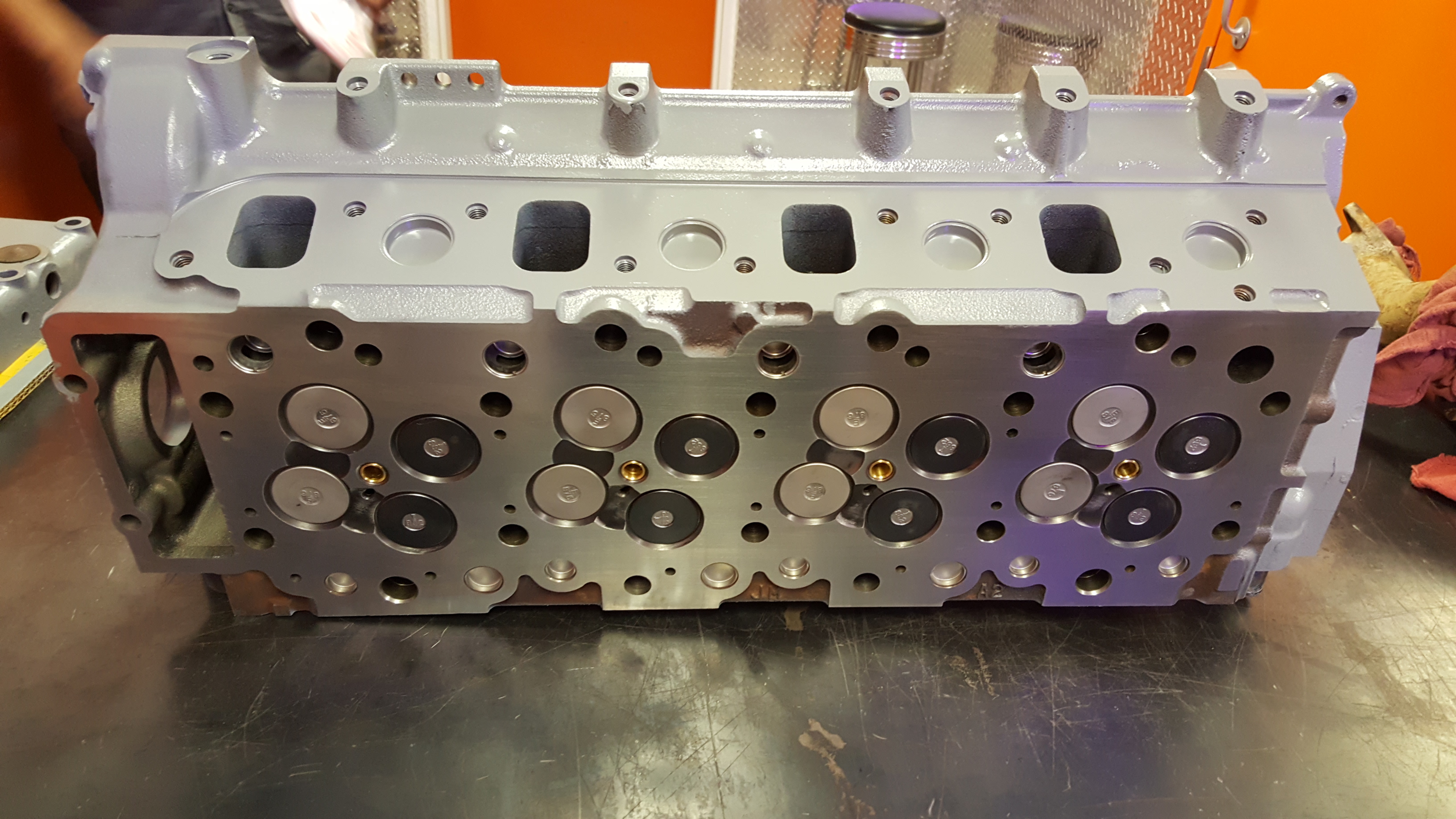

In this video i show you how to water and air pressure test your cylinder heads for valve seating issues right on your bench. If you suspect issues with your cylinder heads a water test is an easy way to confirm your suspicions and show the trouble areas drip by drip. When the leak down test tool is attached to the cylinder the next task is to attach the tool itself to the air compressor. The cycle begins with an air flow test at 2 psig to ensure a minimum flow rate of 220 lpm. But a cylinder leak down test takes it to the next level and measures cylinder pressure loss. Remove the spark plug and place the problem cylinder at tdc top dead center of the compression stroke.

So the compression test measures how much pressure the engine can produce while cranking. Gototop cylinder leak detectorengine compression diagnosis test kitcylinder leakage leakdown leak detector engine compression tester for piston ring valve head gasket. Always make sure to test cylinder leakage with the piston at the top of the cylinder. The cylinder heads must pass both tests to meet test specifications or the test will indicate a reject part. A compression test is a dynamic test engine moving a cylinder leakdown test is a static test engine at rest. Once the compressor hose is connected turn the regulator clockwise to allow the air to flow into the cylinder.

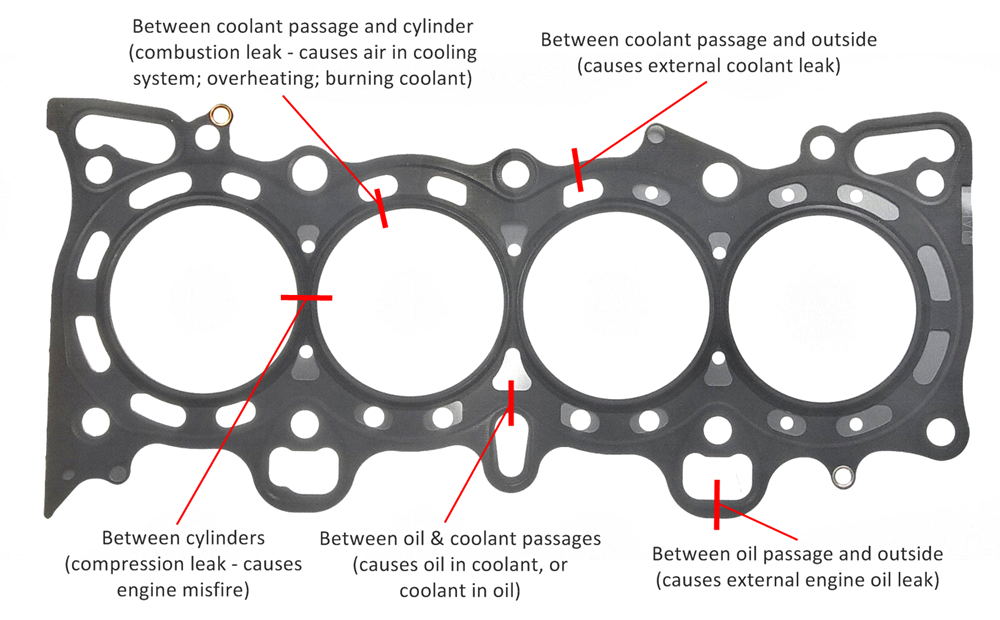

Another way to test for a leaking head gasket is with a radiator pressure test kit. It shows the percentage of leakage and pinpoints the part causing the compression leak.