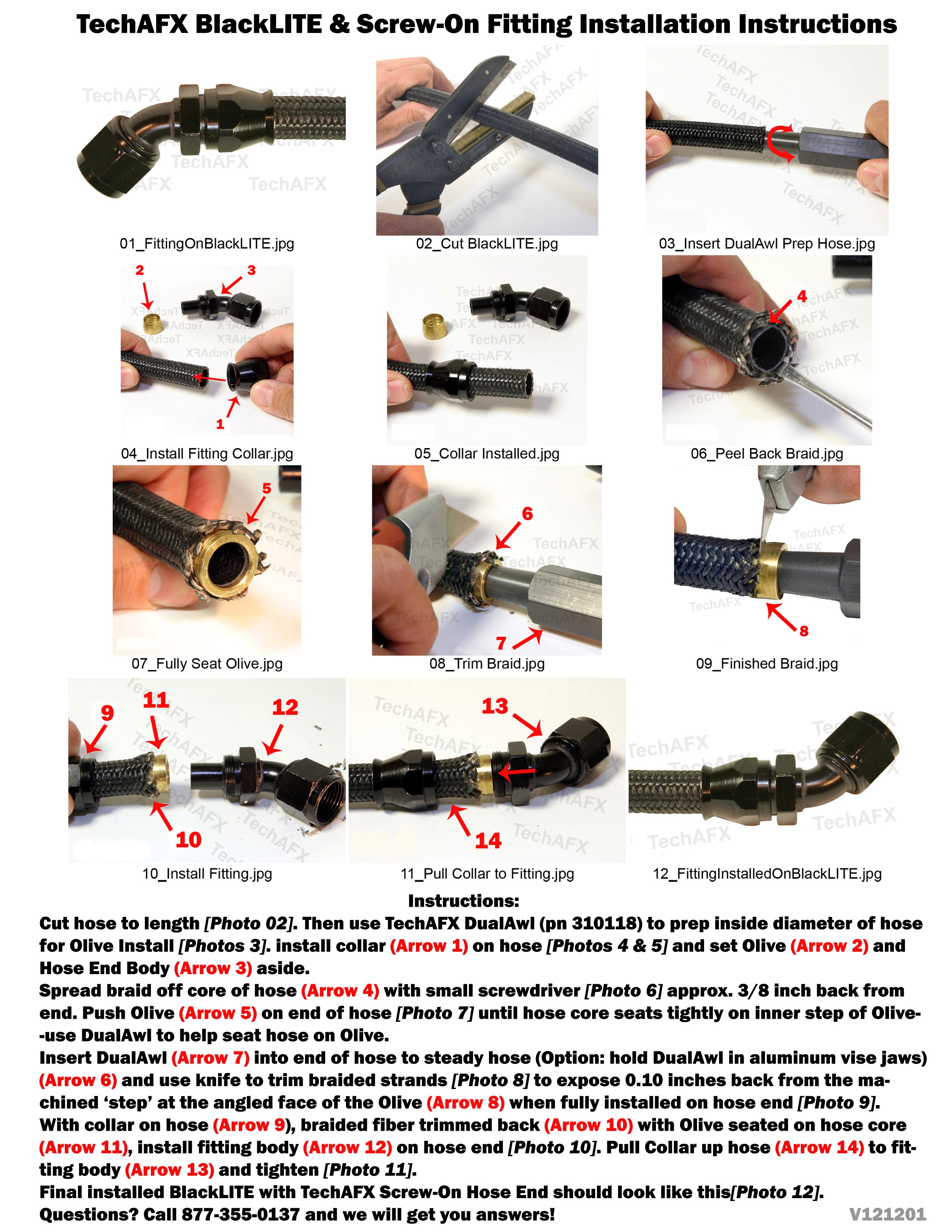

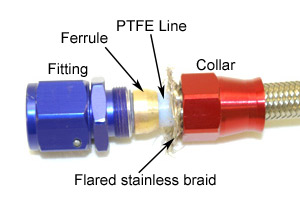

Using an an wrench or equivalent wrench tighten the fitting into the hose end. At each end of the an hose you will require a hose end this is what we call the fittings that are fitted onto the end of the an hose.

How To Check An Hose Assemblies For Leaks

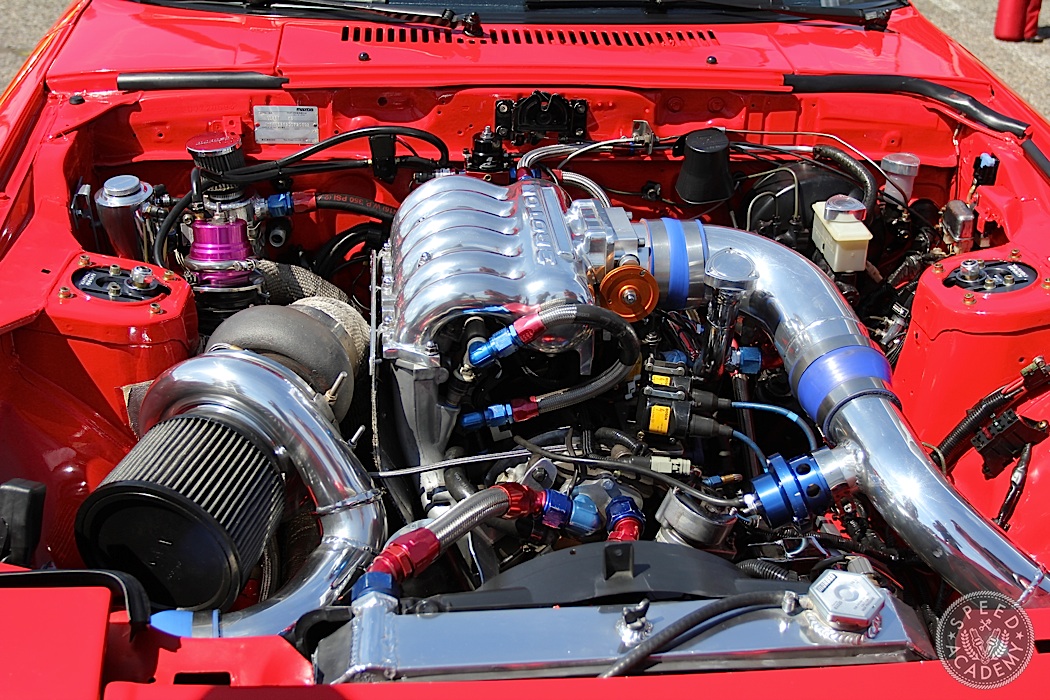

An fittings how to. In this video we go over the basics and some important information about an fittings. As you can see the tape remains tight against the lower fitting. The finished an hose assembly is then ready to be installed. The hose end mechanically fits to the hose in a way that is secure and leak free the following pages show detailed cut through images. A fitting listed at 3 dash three refers to the inside diameter of the fitting for instance a 3 an would fit a metal tube outside diameter of 316 inch. On the other hand an fittings are flare type compression fittings and as such dont require any form of thread sealant.

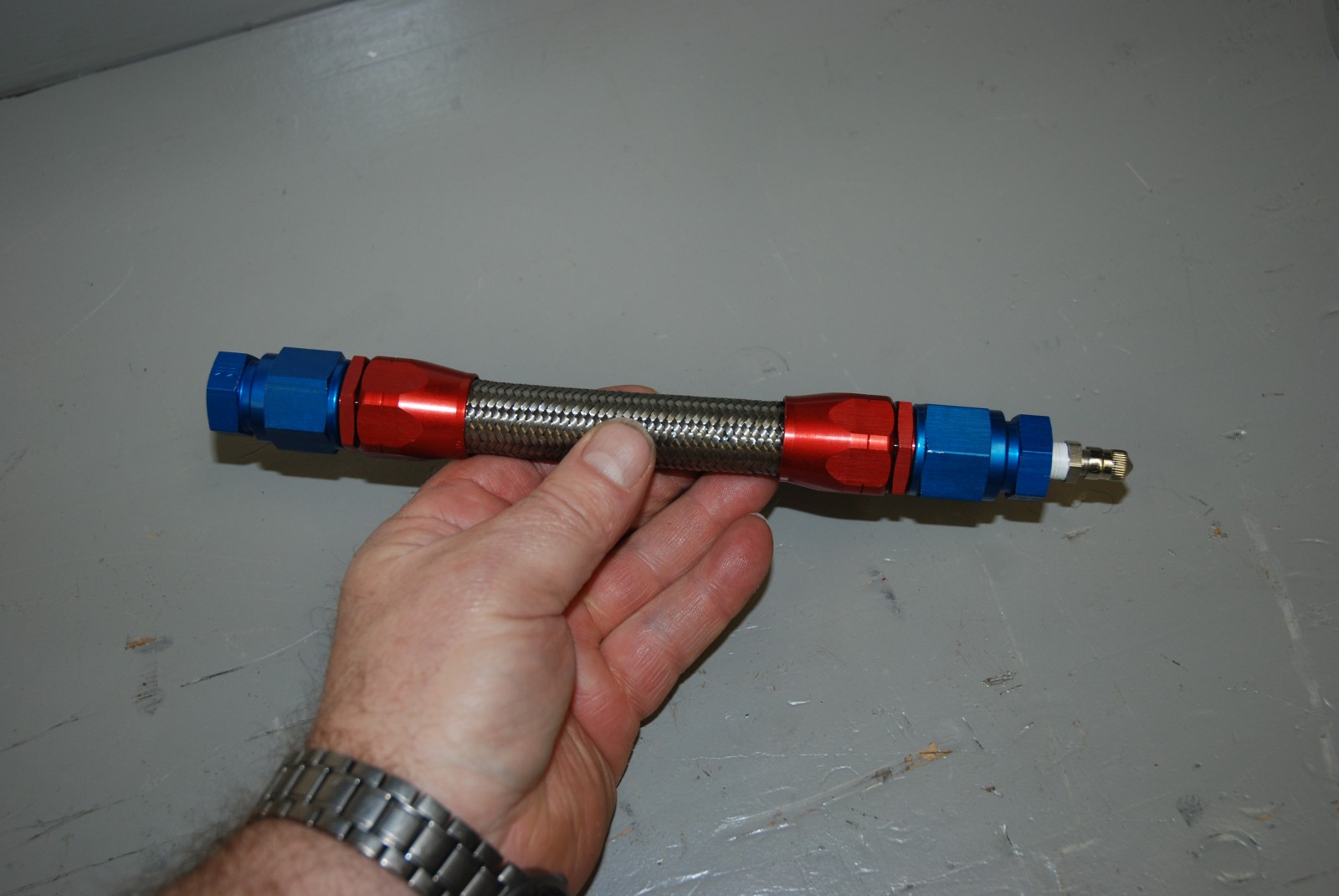

Here is the finished product. Applying an upward pushing motion on the hose simultaneously as you tighten the fitting into the hose also helps to combat the tendency of the hose to be pushed down. An fittings aka army navy fittings are a high quality way to plumb the fluid and even some air lines on your. As a general rule plastic pvc fittings should get ptfe tape wrapped on the threads. Metal threads should be treated with a sealant paste aka pipe dope. An fittings also known as armynavy were originally developed as a military standard that dates back as early as world war ii.