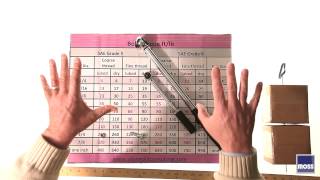

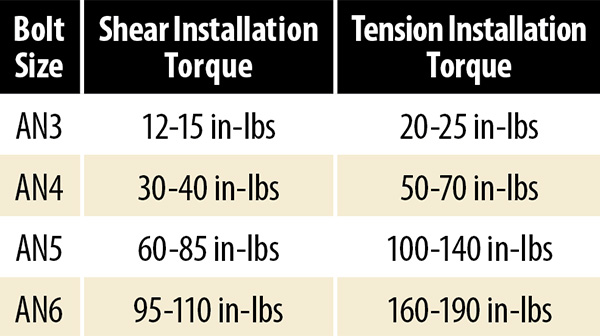

The following torque values are derived from oil free cadmium plated threads. An bolt torque for oil free cadmium plated steel nuts and bolts inch.

Self Locking And Self Sealing Fasteners

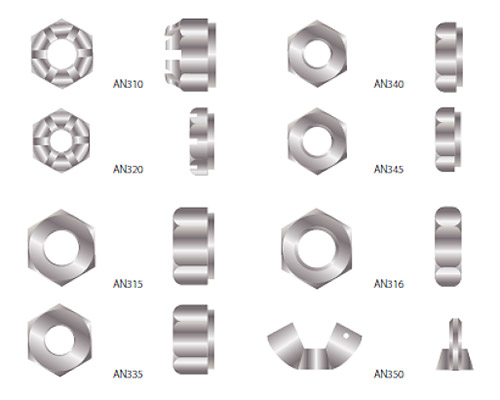

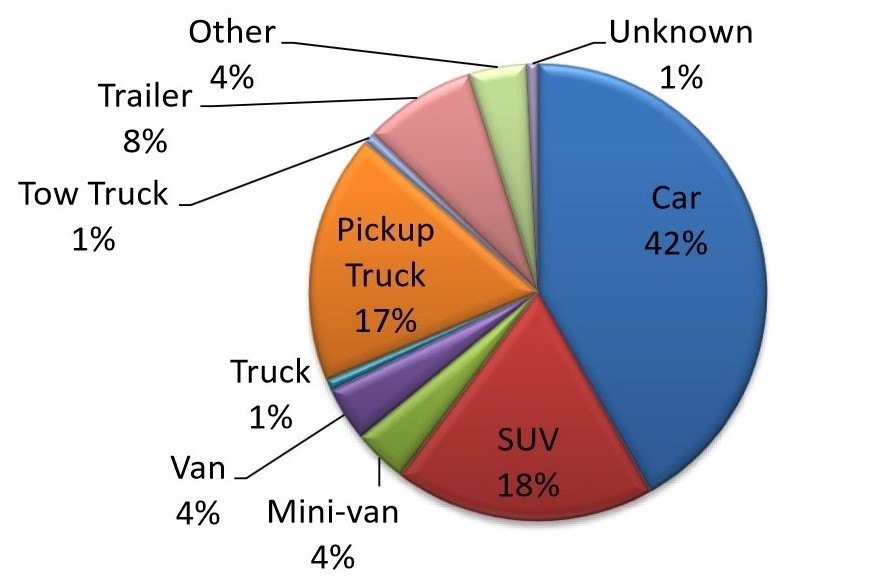

Aircraft bolt torque chart. When securing a fastener use the torque specifications from the following tables. The tension force slightly elongates the bolt. Bolts can be identified by the markings located on the head of each bolt. Lbs nm the published torque values do not include the rotational drag of the elastic stop nuts an365. A random sample of. Standard maintenance practice dictates that mechanics add this value to the specified torque.

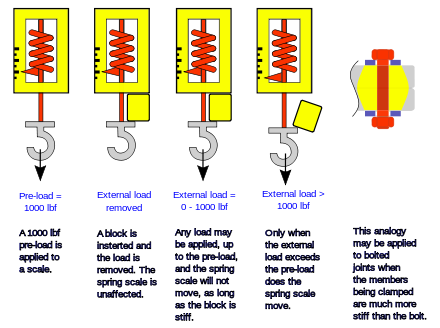

30 understanding bolt torque. This video will help clarify how to use standard torquing procedures found in the chapter 20 standard practices airframe manual. See figure 20 601 when torquing fasteners which do not have a specific torque pattern called out refer to the general torque patterns shown. Ms21919 147 nas1303 nas1320 95 thread size chart 111 ms24566 143 nas1804 98 tinnerman 104 105 ms24665 115 nas bolts 94 95 torque chart 99 ms24693 109 neoprene hose 135 trim kits 80 84 ms24693bb 112 nicopress sleeves 138 turnbuckles 139 142 ms24694 110 nuts airframe 96 98 tubing 135 136 ms25171 149 anchor 51100 103 v vinyl tubing 135. Torque limits recommended for instal lation bolts loaded primarily in shear maximum allowable tightening torque limits thread size tension type nuts ms20365 and an310 40000 psi in bolts shear type nuts ms20364 and an320 24000 psi in bolts nuts ms20365 and. However before you turn to a standard torque chart you should first search for information in the maintenance instructions manual and illustrated parts breakdown that your aircraft manufacturer supplied with your aircraft.

The torque values must 3 4 have been established for average dry cadmium be followed unless the mim or structual repair manual plated nuts for both the fine and coarse thread series of for the specific aircraft requires a specific torque for a nuts. Bolt tension is crucial to ensure that the two jointed surfaces are properly mated together to resist all forces generated by aircraft tires on the light fixture. Thread surface variations such as paint lubri given nut. When a bolt is tightened to a specified torque the bolt is subjected to a tension or preload force. In the case of repair youll look at a standard aircraft torque bolt chart to determine the appropriate level of torque to apply to a bolt youre tightening or replacing.