A the dw in line filters are available in 3 canister sizes. It may need replacing more ofeten than a larger micron filter.

Billet Fuel Filter 10 Micron No Bypass

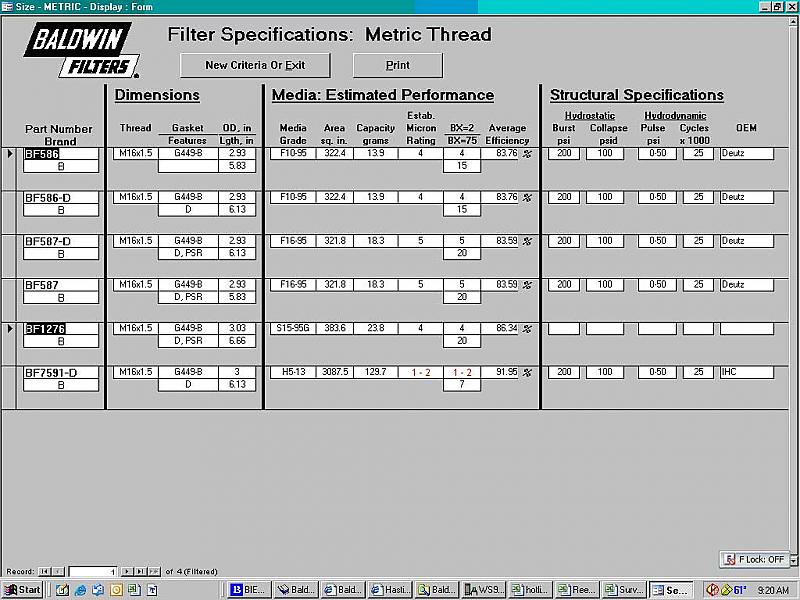

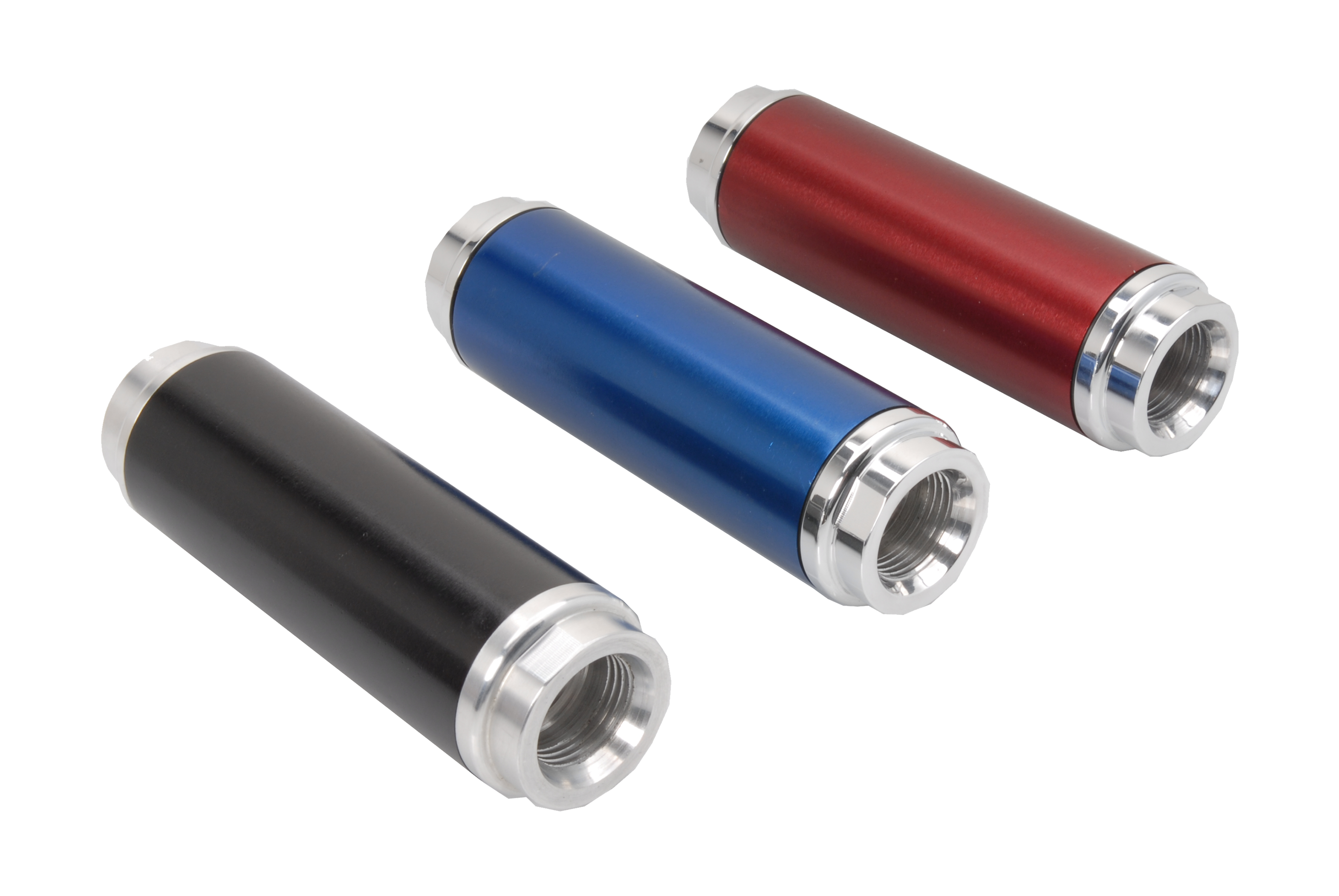

10 micron vs 100 micron fuel filter. When choosing a filter for use after the pump and before the engine use an aeromotive 10 micron part numbers 12301 and 12310 40 micron part number 12335 or an acceptable equivalent. Josh davis from fuelab provides his thoughts on how he guides customers through choosing a fuel filter. Q what size canister should i use. Theres good reason for the confusion. What is the difference between a 10 micron filter and a 100 micron filter answers. Above are various versions of 100 micron fuel filterselements.

Any filter used after the pump must meet the following requirements. Common e10e15 pump gas is. 10 micron this rating filters a little less than the 5 micron rating. Filters with a larger micron rating allow larger particles through the system. The top element is the aeromotive 100 micron element pn 12604 as found the fuel filter assembly pn 12304. A 30 micron filter used in an unleaded dispenser unit can allow unwanted particles to pass through to the customers.

1030 micron primary filter element debate is one that has raged for several years now and i suspect the end is nowhere in sight and it applies to all diesel engines from 10 hp sail auxiliaries to engines like yours. The 10 micron paper element is good for pump gas and race gas but not alcohol based fuels. A finer micron filter can collect more contamination from the fuel and reach its dirt holding capacity more quickly. This is a great question. Usually a 10 micron filter is used for unleaded gasoline and a 30 micron filter is used for diesel fuel. These filters are for use on the fuel pump outlet side only.

Filter material is measured in microns. Filters with a 10 micron rating can remove some unseen materials from liquid but not bacteria or viruses. A ten micron filter will remove smaller particles from thesystem but will also clog faster. Fluid in 100 particles 5 microns upstream of filter 1 particle 5 microns downstream of. Note the various filters all have billet housing with an connections and can be disassembled for inspection and cleaning. A 100 micron filter element should be installed between the tank and the pump and a 10 micron filter element should be installed between the pump and the injectors.

Larger canister sizes provide less flow restriction and increased service intervals. However 10 micron is still very small and can benefit many industries from oil to chemical plants because of their ability to filter so much. A good filter is low cost protection for expensive engine components. Personally i prefer to see our 10 micron or 6 micron element after the pump on both carbureted and efi applications.