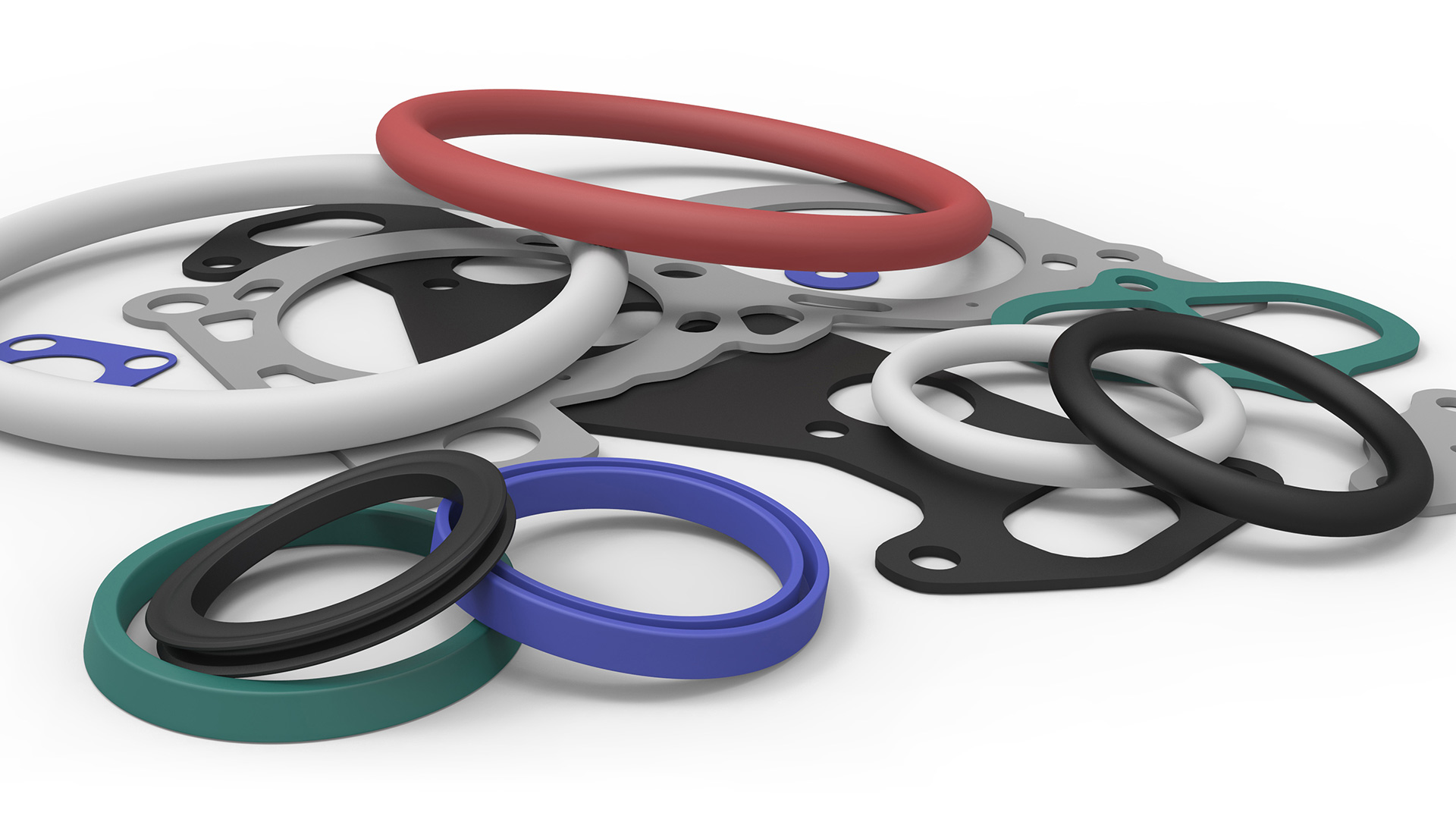

Ethylene propylene rubber epr o rings. An o ring also known as a packing or a toric joint is a mechanical gasket in the shape of a torus.

More O Ring Manufacturer Listings

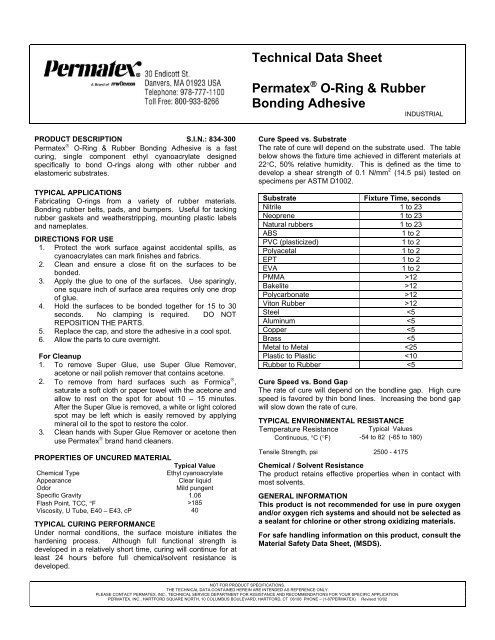

O ring rubber material. When pressure is applied to the system this also helps the o ring seal by pushing the o ring against the groove wall opposite the direction of the pressure and forcing it. We have been specialized in manufacturing quality rubber products since 1994. This memory is how the o rings seal under low to no pressure. What is the best o ring material for the application. Unlike viton o rings ethylene propylene rubber epr o rings are suitable for use with corrosive skydrol hydraulic fluid as well as steam water silicone oils brake fluids and alcohols. The diversity of o ring applications in large part is due to the wide variety of material used in its fabrication.

In other words it wants to go back to its original shape. O rings are one of the most common seals used in machine design today. It has an operating temperature of 75 to 400f 59 to 204c and a hardness range of 50 80 durometer. When an o ring is squeezed the rubber has a memory. It is a loop of elastomer with a round cross section designed to be seated in a groove and compressed during assembly between two or more parts creating a seal at the interface. When you find one that fits your application click on the o ring material for a deeper dive on technical specifications to further assist you in o ring material selection.

This material is known to display good heat and compression resistance. A type of saturated rubber material that offers good stability in extreme temperatures and resists fuels oils solvents chemicals and more. O rings are manufactured with elastic polymers known as elastomers. Identifying a damaged o ring and how to fix it. This popular o ring material family comparison shows basic rubber material family properties and performance plastic properties. The o ring may be used in static applications or in dynamic applications where there is relative motion between.

O ring material quick reference guide rubber sealing materials. O ring material family chemical compatibility temperature resistance and other properties all factor in to o ring material selection for an application. Providing you with timely online service and quick delivery we warmly welcome you to buy our products. This rubber seal material from yiho polytek enjoys the advantages of high ozone and chemical resistance good flexibility and elasticity excellent oil resistance etc. The o ring material comparison chart below offers a quick reference of o ring material performance. A mechanical gasket in the shape of a doughnut an o ring is a loop of elastomer with a round cross section designed to be placed in a groove and compressed during assembly between two or more parts creating a seal at the interface.